- Electrical Training

- Safety

- Electrical Compliance

- Electrical Automation

- Electrical Maintenance

- Mechanical Training

- HVAC

- Codes and Standards

- Fluid Power

- Maintenance

- View All Training Programs

-

View All Electrical Safety Training ProgramsTop Electrical Safety Training Programs

- Arc Flash Electrical Safety [Based on NFPA 70E®]

- Electrical Safety: NFPA 70E Refresher

- Electrical Safety Awareness

- Electrical Safety Practical Skills for Switchgear

- Electrical Safety: Power Generation, Transmission & Distribution [based on OSHA 1910.269]

- Seguridad Eléctrica en el centro de trabajo, [Basado en el manual NFPA 70E® 2021]

Upcoming Training Programs- 11/29 - 11/29 : Live Online Training , CO Electrical Safety: NFPA 70E Overview - NEW!

- 12/02 - 12/03 : Atlanta , GA Arc Flash Electrical Safety [Based on NFPA 70E®]

- 12/09 - 12/10 : Live Online Training , CO Arc Flash Electrical Safety [Based on NFPA 70E®]

- 12/09 - 12/10 : Centennial , CO Arc Flash Electrical Safety [Based on NFPA 70E®]

- 12/09 - 12/10 : Orlando , FL Arc Flash Electrical Safety [Based on NFPA 70E®]

-

View All Electrical Electrical Compliance Training ProgramsTop Electrical Electrical Compliance Training Programs

- 2020 NFPA 70® – National Electrical Code® [NEC]

- 2023 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

- Electrical Systems: SOARS Grounding & Bonding

- Electrical Systems: Hazardous Locations

- NEC® – Analysis of Changes 2020 with Practical Exercises

- NFPA 110® – Emergency & Standby Power Systems

- NFPA 70B® Standard Overview

- NFPA 70B® – Standard For Electrical Equipment Maintenance®

- NFPA 72: National Fire Alarm & Signaling Code®

- 2021 NFPA 79® – Electrical Standard For Industrial Machinery®

- NICET I & II

- National Electrical Safety Code® [NESC]

- NEC® – Analysis of Changes 2023

Upcoming Training Programs- 12/04 - 12/06 : Atlanta , GA 2023 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

- 12/11 - 12/13 : Centennial , CO 2023 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

- 12/11 - 12/13 : Live Online Training , CO 2023 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

- 12/11 - 12/13 : Orlando , FL 2023 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

- 12/11 - 12/12 : Live Online Training , CO NICET I & II

-

View All Electrical Electrical Automation Training ProgramsTop Electrical Electrical Automation Training Programs

- Instrumentation & Process Control

- PLCs [Programmable Logic Controllers]: Automation Systems

- PLCs [Programmable Logic Controllers]: ControlLogix & RSLogix 5000

- PLCs [Programmable Logic Controllers]: Fundamentals

- PLCs [Programmable Logic Controllers]: Siemens Simatic S7

- Tuning DDC/Process Control Loops

- Variable Frequency Drives [VFD]

Upcoming Training Programs- 12/09 - 12/11 : Philadelphia , PA PLCs [Programmable Logic Controllers]: Fundamentals

- 12/12 - 12/13 : Philadelphia , PA PLCs [Programmable Logic Controllers]: Automation Systems

- 02/04 - 02/06 : Centennial , CO Variable Frequency Drives [VFD]

- 04/07 - 04/09 : Centennial , CO PLCs [Programmable Logic Controllers]: Fundamentals

- 05/20 - 05/22 : Centennial , CO Variable Frequency Drives [VFD]

-

View All Electrical Electrical Maintenance Training ProgramsUpcoming Training Programs

- 11/21 - 11/22 : Centennial , CO Electrical Motor Control Circuits: Troubleshooting

- 11/25 - 11/26 : Live Online Training , CO Electrical Print Reading: Blueprints & Schematics

- 11/29 - 11/29 : Live Online Training , CO Electrical Safety: NFPA 70E Refresher

- 12/03 - 12/04 : Orlando , FL Basics of Industrial Electricity

- 12/05 - 12/06 : Orlando , FL Electrical Motor Control Circuits: Troubleshooting

-

View All Mechanical HVAC Training ProgramsTop Mechanical HVAC Training Programs

- Balancing of Water and Air Systems

- Boilers: An Operational Workshop

- HVAC: Brazing [Advanced]

- Air Conditioning & Refrigeration: Advanced

- HVAC: Air Conditioning & Refrigeration

- HVAC: Principles of Heating & Ventilation

- Chillers: Operation & Maintenance of Chilled Water Systems

- Steam Distribution Systems

- Water Treatment for Boilers and Chilled Water Systems

Upcoming Training Programs- 12/03 - 12/05 : Saint Louis , MO HVAC: Air Conditioning & Refrigeration

- 12/03 - 12/05 : Seattle , WA Chillers: Operation & Maintenance of Chilled Water Systems

- 12/05 - 12/06 : Live Online Training , CO Boilers: An Operational Workshop

- 12/09 - 12/11 : Centennial , CO HVAC: Air Conditioning & Refrigeration

- 12/10 - 12/12 : Elk Grove , IL HVAC: Air Conditioning & Refrigeration

- View All Mechanical Codes and Standards Training Programs

-

View All Mechanical Fluid Power Training ProgramsUpcoming Training Programs

- 12/03 - 12/05 : Centennial , CO Pneumatics & Electro Pneumatics Systems

- 12/10 - 12/13 : Seattle , WA Hydraulics & System Troubleshooting

- 12/10 - 12/12 : Centennial , CO Centrifugal Pumps

- 01/21 - 01/24 : Centennial , CO Hydraulics & System Troubleshooting

- 03/11 - 03/14 : Centennial , CO Hydraulics & System Troubleshooting

-

View All Mechanical Maintenance Training ProgramsUpcoming Training Programs

- 12/03 - 12/05 : Centennial , CO Mechanical Drives & Power Transmission

- 02/06 - 02/07 : Centennial , CO Shaft Alignment with Laser Technology

- 03/04 - 03/05 : Centennial , CO Electric Motors: Understanding & Troubleshooting

- 05/06 - 05/07 : Centennial , CO Electric Motors: Understanding & Troubleshooting

- 05/08 - 05/09 : Centennial , CO Shaft Alignment with Laser Technology

Select the following link if you would like to recover a report that has been previously deleted.

NTT Blog

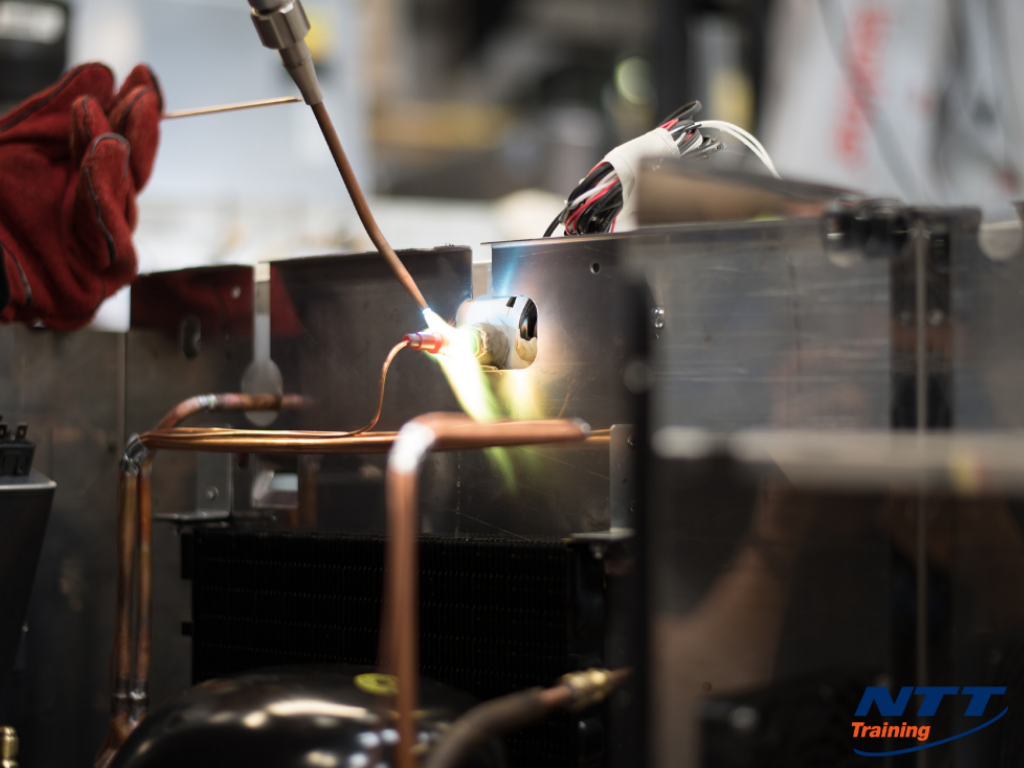

HVAC Brazing: When Your Employees Are Ready for Advanced Techniques

Brazing, welding, and soldering are the techniques used to join metal to metal. You principally employ brazing and soldering when you’re working in HVAC. You will need to know when to solder and when to braze.

Brazing correctly means you’ll have a system that works right, standing up to extremes of pressure and temperature. If you do it wrong, joints will fail, as will the system they are designed to support.

Brazing might be taught after the technician has learned welding or soldering, or in conjunction with them. Some of the same safety issues are involved in brazing as soldering, although the brazer will be working with significantly hotter temperatures. Brazers are also exposed to fumes, which are released when temperatures are too hot. Proper training and practice can help the brazer control the temperature to ensure safe working conditions.

What Is Brazing?

Here’s the difference between soldering, brazing, and welding.

Soldering — Join two metals by melting a third filler metal between them, without melting the two metals.

Brazing — Same as soldering, but the filler metal melts above 840 degrees F, so is much hotter than soldering. High temperatures create a stronger bond.

Welding — Two metals joined by melting them together, but involves even hotter temperatures than the above two methods. Welded joints are the strongest.

Welds offer the strongest bond but are not needed in the copper lines used in HVAC, a brazed joint being considered strong enough. Sometimes even a soldered joint is enough. There are some situations when brazing may be too hot, so the technician will have to exercise care and judgment and perhaps use soldering instead. Sometimes, when joining copper tubing to an air conditioner unit, you have to be careful so as not to damage rubber or nylon bushings with the hotter temperatures.

The main reason a brazed joint is often preferred in HVAC work is that it’s virtually leak-proof.

Most brazers use an oxygen-acetylene torch for brazing, as it gets hotter than the types of torches used for soldering. A turbo torch may also work.

Brazing rods, similar in appearance to straightened metal coat hangers, are stronger, the more silver they have in them. To join copper lines in HVAC work, a technician will usually use brazing rods made of a copper-phosphorous combination. Lines must be heated until they are glowing red, so the technician has to keep the torch moving or a hole can be burned through the copper tubing.

Teaching Brazing

Brazing can be taught in a classroom, but beginners need practice and professional instruction to become proficient. Beginning students must contend with flammable items, difficult access, and awkward positions.

The student must learn proper adjustment and metering of acetylene and oxygen. Some of the basic brazing procedures they will be taught are:

- Fitting, supporting joints.

- Degree of heating, cleaning tubing, and parts to be used.

- How to heat evenly, moving flame in figure 8.

- Waiting for flame to turn green.

- Applying brazing rod (avoiding melting with torch).

- Cooling joints.

Experienced instructors can help student brazers improve results when working in the HVAC industry. For instance, students might learn that joints must be carefully heated so that parts aren’t damaged, and that damaged parts should be wrapped in wet rags to protect them. They might also learn that the proper level of nitrogen pushing through a refrigeration or air conditioning system will reduce copper oxidation, and compressor failure rates.

Proper brazing techniques can be taught in the classroom or in the field.

A Course in Brazing

If your employees could benefit by adding brazing to their soldering or welding skills, consider providing them a training. Some of the persons on your team who might benefit are:

- Building engineers

- Stationary engineers

- Plant and facility maintenance technicians

- HVAC maintenance and repair technicians

- Building managers, superintendents

- Apprentice or experienced HVAC technicians

As far as topics that should be covered in the course, look for training in these skills:

- Brazing

- Soldering

- Working with copper

- Bronze welding

- Work-hardening and precipitation hardening

- Joining dissimilar metals (metallurgical factors)

Also helpful: advanced A/C, boilers, basic electricity, and air and water balancing.

For the brazing component of a course, the student should receive instruction in some or all of these topics:

- Brazing filler metals

- Silver and copper alloys, plus silver-copper-phosphorous alloys

- Designing joints

- Brazing alloy pre-placement

- Coppers

- Physical/metallurgical factors

- Precipitation-hardening copper alloys

- Cold-worked alloys, or with high softening temperatures

A course in brazing should also teach proper safety procedures, and what sort of protective and safety equipment is needed, including clothing and gloves, and goggles or face masks.

Proper Brazing Techniques Help Extend Life of HVAC Equipment

Help your employees improve their brazing techniques and the outcomes of their work with HVAC equipment with a three-day hands-on seminar on HVAC: Brazing (Advanced). Learn more from NTT Training.

Recent Blog Posts

- Continuing Education Course for Connecticut Electricians (4-hr)

- Michigan Section 8 Rules and Their Application Regarding the NEC

- Confined Space Entry: How to Ensure Safe and Successful Operations

- How To Start a PM Program

- Confined Space Programs

- Categories

- Uncategorized (18)

- Electrical Training Programs (94)

- Code & Standards (29)

- Electrical Maintenance (17)

- Mechanical HVAC (8)

- Safety (39)

- Mechanical Training Programs (74)

- Code & Standards (10)

- Electrical Safety (8)

- HVAC (17)

- Maintenance (19)

- Fluid Power (19)

- News (13)

- Onsite Training (2)

- Contractor Management (1)

- National Electric Code (6)

- OSHA Rules and Requirements (18)

- General Safety Tips (3)

- Industrial Safety (4)

- Plumbing Standards (2)

- Electrical Blueprint Reading (6)

- Natural Gas Safety (3)

- Ultrasonic Testing (1)

- PLC (10)

- High Voltage (3)

- Oil Analysis (2)

- Centrifugal Pumps (4)

- Variable Frequency Drives (6)

- Welding Safety (7)

- Chillers (3)

- Hazardous Locations (5)

- Confined Spaces (6)

- Infrared Thermography (2)

- NFPA 72 (4)

- Process Control Loops (3)

- Backflow Prevention (1)

- Electrical Grounding (2)

- Industrial Circuits (2)

- Boilers (5)

- Shaft Alignment (3)

- Hoisting and Rigging (3)

- Fiber Optics (5)

- Refrigeration (1)

- Arc Flash (8)

- NFPA 110 (1)

- Conveyor Systems (1)

- NFPA 70E (2)

- Process Instruments (1)

- Vibration Analysis (1)

- Industrial Generators (1)

- Life Safety Code (1)

- Electrical Switchgear (1)

- NFPA 79 (1)

- Steam Distribution Systems (1)

- Preventative Maintenance (1)

Filter Blogs

- October 2024 (1)

- September 2024 (1)

- August 2023 (1)

- July 2023 (1)

- June 2023 (1)

- April 2023 (1)

- March 2023 (1)

- February 2023 (1)

- December 2022 (1)

- October 2022 (1)

- August 2022 (1)

- July 2022 (1)

- October 2019 (9)

- September 2019 (8)

- August 2019 (9)

- July 2019 (8)

- June 2019 (8)

- May 2019 (9)

- April 2019 (9)

- March 2019 (7)

- February 2019 (4)

- January 2019 (9)

- December 2018 (7)

- November 2018 (7)

- October 2018 (9)

- September 2018 (6)

- August 2018 (7)

- July 2018 (9)

- June 2018 (8)

- May 2018 (9)

- April 2018 (9)

- March 2018 (8)

- February 2018 (8)

- January 2018 (9)

- December 2017 (9)

- November 2017 (8)

- October 2017 (9)

- September 2017 (8)

- August 2017 (7)

- July 2017 (5)

- June 2017 (7)

- May 2017 (8)

- April 2017 (3)

- March 2017 (7)

- February 2017 (3)

- January 2017 (4)

- December 2016 (7)

- November 2016 (4)

- October 2016 (7)

- September 2016 (5)

- August 2016 (6)

- June 2016 (1)

- May 2016 (2)

- April 2016 (2)

- March 2016 (1)

- January 2016 (2)

- October 2015 (1)

- August 2015 (1)

- July 2015 (3)

- May 2015 (1)

- March 2015 (1)

- January 2015 (3)

- April 2014 (4)

Our Mission:

"Deliver solutions to our clients (and their global workforce) designed for safety, productivity and profitability.”

NTT Training Inc. has been accredited by the Accrediting Council for Continuing Education & Training (ACCET).

Better Business Bureau

Better Business Bureau

A Training Division of ECPI University