- Electrical Training

- Safety

- Electrical Compliance

- Electrical Automation

- Electrical Maintenance

- Mechanical Training

- HVAC

- Codes and Standards

- Fluid Power

- Maintenance

- View All Training Programs

-

View All Electrical Safety Training ProgramsTop Electrical Safety Training Programs

- Arc Flash Electrical Safety [Based on NFPA 70E®]

- Electrical Safety: NFPA 70E Refresher

- Electrical Safety Awareness

- Electrical Safety Practical Skills for Switchgear

- Electrical Safety: Power Generation, Transmission & Distribution [based on OSHA 1910.269]

- Seguridad Eléctrica en el centro de trabajo, [Basado en el manual NFPA 70E® 2021]

- Electrical Safety, Operation and Maintenance for Medium Voltage (MV) Distribution Systems and Equipment

- Train-The-Observer: Electrical Safety Field Observer Training

Upcoming Training Programs- 04/06 - 04/07 : Live Online Training , CO Arc Flash Electrical Safety [Based on NFPA 70E®]

- 04/30 - 04/30 : Centennial , CO Electrical Safety Practical Skills for Switchgear

- 05/04 - 05/05 : Live Online Training , CO Arc Flash Electrical Safety [Based on NFPA 70E®]

- 06/01 - 06/02 : Live Online Training , CO Arc Flash Electrical Safety [Based on NFPA 70E®]

- 06/23 - 06/24 : Centennial , CO Electrical Safety, Operation and Maintenance for Medium Voltage (MV) Distribution Systems and Equipment

-

View All Electrical Electrical Compliance Training ProgramsTop Electrical Electrical Compliance Training Programs

- 2026 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

- New Jersey 1 Hour Electrical Law (License Requirement)

- Electrical Systems: SOARES Grounding & Bonding

- Electrical Systems: Hazardous Locations

- NEC® – Analysis of Changes 2020 with Practical Exercises

- NFPA 110® – Emergency & Standby Power Systems

- NFPA 70B® Standard Overview

- NFPA 70B Standard for Electrical Equipment Maintenance (8-hr for Maintenance Technicians)

- NFPA 72: National Fire Alarm & Signaling Code®

- NFPA 79® – Electrical Standard For Industrial Machinery®

- NICET I & II

- National Electrical Safety Code® [NESC]

- NEC® – Analysis of Changes 2023

- Connecticut Four Hour 2025 Electricians Continuing Education Course

- 2023 National Electrical Code® With 2023 Washington State’s Electrical Code Amendments (based on Washington Administrative Code 296-46B)

Upcoming Training Programs- 04/08 - 04/10 : Centennial , CO 2026 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

- 04/08 - 04/10 : Live Online Training , CO 2026 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

- 04/29 - 04/30 : Live Online Training , CO Electrical Systems: Hazardous Locations

- 05/06 - 05/08 : Live Online Training , CO 2026 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

- 06/03 - 06/05 : Live Online Training , CO 2026 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

-

View All Electrical Electrical Automation Training ProgramsTop Electrical Electrical Automation Training Programs

- Instrumentation & Process Control

- PLCs [Programmable Logic Controllers]: Automation Systems

- PLCs [Programmable Logic Controllers]: ControlLogix & RSLogix 5000

- PLCs [Programmable Logic Controllers]: Fundamentals

- PLCs [Programmable Logic Controllers]: Siemens Simatic S7

- Tuning DDC/Process Control Loops

- Variable Frequency Drives [VFD]

Upcoming Training Programs -

View All Electrical Electrical Maintenance Training ProgramsUpcoming Training Programs

- 04/02 - 04/03 : Centennial , CO Electrical Motor Control Circuits: Troubleshooting

- 04/07 - 04/09 : Centennial , CO Fiber Optics

- 05/12 - 05/13 : Centennial , CO Basics of Industrial Electricity

- 05/14 - 05/15 : Centennial , CO Electrical Motor Control Circuits: Troubleshooting

- 07/07 - 07/09 : Centennial , CO Fiber Optics

-

View All Mechanical HVAC Training ProgramsTop Mechanical HVAC Training Programs

- Balancing of Water and Air Systems

- Boilers: An Operational Workshop

- HVAC: Brazing [Advanced]

- Air Conditioning & Refrigeration: Advanced

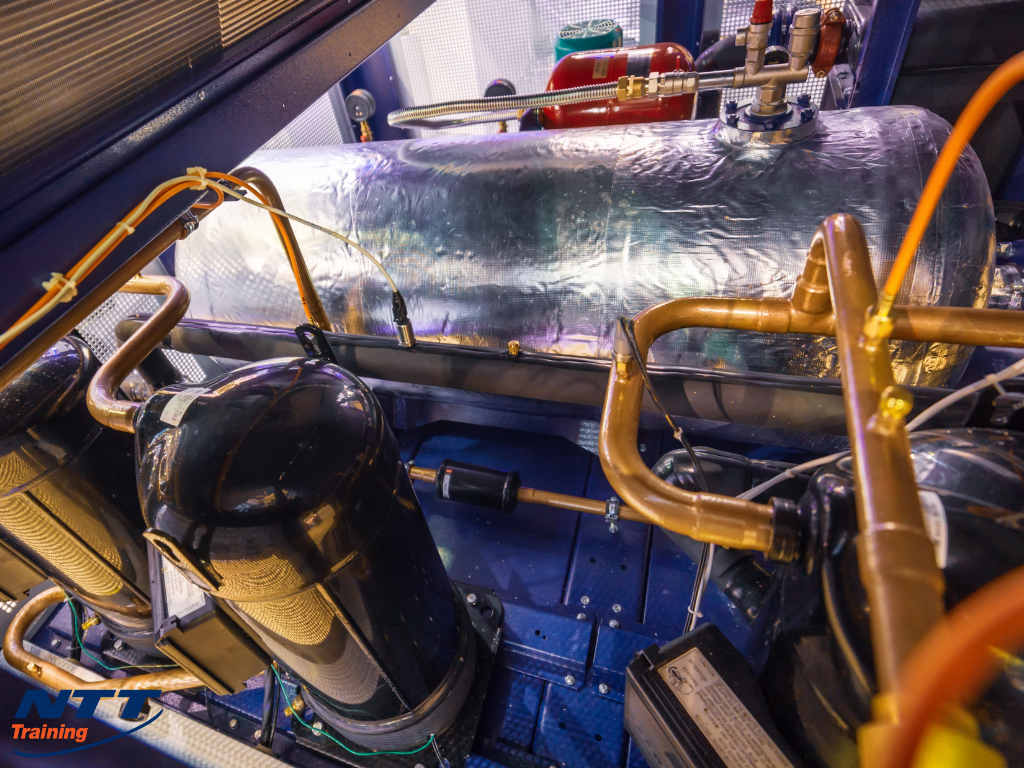

- HVAC: Air Conditioning & Refrigeration

- HVAC: Principles of Heating & Ventilation

- Chillers: Operation & Maintenance of Chilled Water Systems

- Steam Distribution Systems

- Water Treatment for Boilers and Chilled Water Systems

- EPA 608 Certification Exam Preparation & Proctoring

Upcoming Training Programs- 05/19 - 05/21 : Centennial , CO Boilers: An Operational Workshop

- 06/08 - 06/10 : Centennial , CO HVAC: Air Conditioning & Refrigeration

- 06/11 - 06/11 : Centennial , CO EPA 608 Certification Exam Preparation & Proctoring

- 06/12 - 06/12 : Live Online Training , CO EPA 608 Certification Exam Preparation & Proctoring

- 07/07 - 07/09 : Centennial , CO Chillers: Operation & Maintenance of Chilled Water Systems

- View All Mechanical Codes and Standards Training Programs

- View All Mechanical Fluid Power Training Programs

-

View All Mechanical Maintenance Training ProgramsUpcoming Training Programs

- 05/05 - 05/06 : Centennial , CO Electric Motors: Understanding & Troubleshooting

- 05/07 - 05/08 : Centennial , CO Shaft Alignment with Laser Technology

- 07/28 - 07/29 : Centennial , CO Electric Motors: Understanding & Troubleshooting

- 08/06 - 08/07 : Centennial , CO Shaft Alignment with Laser Technology

- 11/03 - 11/04 : Centennial , CO Electric Motors: Understanding & Troubleshooting

Select the following link if you would like to recover a report that has been previously deleted.

NTT Blog

HVAC Brazing: Are Your Employees Ready for Advanced Instruction?

Brazing is the safest and most preferred method of joining in HVAC due to its ability to produce corrosion-resistant, pressure-tight, and high tolerance precision joints.

The process requires a keen eye, even the smallest oversight could be catastrophic. The skill gap in the labor market is forcing more and more manufacturing firms to train their technical staff rather than hire a new staff member.

According to the Bureau of Labor Statistics, hiring a brazing technician can be expensive and skilled brazers could be difficult to locate. Unless necessary, the headaches and disappointments of the hiring process can be avoided by simply training your current employees.

What Is Brazing for HVAC?

Brazing is the process of joining similar or dissimilar metals. Filler metal is drawn by capillary action into space between the two adjacent pieces to be joined.

For this to happen, the filler metal must have a lower melting point than the parent metal components being joined. Alloys used in brazing are commonly made of copper and zinc in varying proportions. In HVAC brazing is used in joining the tube fittings and heat exchangers.

The Basic Principles of Brazing

- Clearance: Before brazing, you must ensure that the clearance is optimum. If the clearance is too small, there is no room for the molten filler metal to flow through. A larger clearance limits capillary action. Unless you are brazing similar metals such as a copper tube to copper tube, ensure to factor in the coefficient of expansion.

- Cleaning: Contaminated surfaces hinder capillary action. The common contaminants are dirt, oil and or metallic particles. These can be removed by chemical treatment or using an abrasive material. Brazing without cleaning causes leaky joints. Cleaning is also done after brazing to remove excess flux.

- Fluxing: Metals chemically combine with oxygen when heated to form oxides. The application of a chemical compound to prevent oxidation is known as fluxing. When brazing copper to copper in HVAC, a phosphorus filler metal is used since it acts as a fluxing agent.

- Joining/Brazing: The process of brazing can be simplified into the two-step process. You first heat the base metal then apply the filler metal. A gas torch is the most common type of heating used. The torch is set to a soft reducing flame that is large enough to heat both the tube and fitting simultaneously. Sweep the heat back and forth for uniform heating. Other brazing techniques include drip brazing, furnace brazing, and vacuum brazing.

Which Employees are Eligible to Study Brazing?

One benefit of re-training your technical staff is that you already know your workers’ strengths and weaknesses. A manager can choose to train the struggling technical staff to improve their confidence. Such workers can benefit from refresher courses in safety and precautions.

And, for advanced courses, you can enroll your best-performing workers. Fortunately, this particular training is beneficial to both seasoned and apprentice HVAC technicians, building engineers, supervisors and plant maintenance workers.

Industrial Applications of Brazing

- Pipe fittings such as heat exchangers, axles, tanks, and radiators are joined by brazing

- Brazing is used in the assembly of components such as bicycle frames, rims, and metal furniture

- Brazing is used in the creation of artistic objects like chandeliers and brass musical instruments

- Eyewear frames and hinges are joined by brazing because they are thin and delicate, an example is Aviator sunglasses

- Brazing is used in automotive manufacturing to join delicate components

- Measuring instruments such as pressure switches and thermostats are joined by brazing

Benefits of Having a Trained Brazing Technician

Cost-effective: Trained workers eliminate the need to hire new staff members either on a short term or permanently. The hiring process drains resources in the form of advertisement fees, interviews, and higher administrative costs.

Improved Productivity: Having trained brazing technician reduces the mistakes. There are fewer interruptions due to such mistakes and subsequent break downs. It takes less time to repair machines and resume production.

Higher Safety Standards: Just like welding, brazing involves heating at very high temperatures. Trained brazing technicians correctly use the machines, wear protective gears and are always on the lookout for danger. Unlike untrained workers who are a danger to their colleagues and themselves.

They can Help Junior Workers: Trained brazing technicians can guide the junior employees appropriately on various matters. From safety issues to troubleshooting equipment and finished products.

Reduced Employee Turnover: Training employees reduces the need to replace workers who have either resigned or have been dismissed. Training employees shows workers than the company cares about their development and fosters loyalty.

Register Your Workers Today!

Hiring new staff members may seem like a quick simple fix. It might be necessary in some cases but it is not always the answer. If you get it wrong during the hiring process it might be a very costly oversight.

Fortunately for all managers, you don’t have to gamble anymore. NTT Training is the training partner you need. We provide customized training to fit your schedule and desired outcome. Register your workers for the ACCET accredited training in advanced HVAC Brazing. Connect with us today to discuss your company’s training needs.

Recent Blog Posts

- Expert Guide to NEC Compliance in New Jersey

- Why Electrical Safety Observer Training Is the Missing Link in NFPA 70E Compliance

- NEC: National Electric Code (2026 edition)

- NFPA 79: Electrical Standard for Industrial Machinery (2024 Edition)

- EPA 608 Certification and Training

- Categories

- Uncategorized (6)

- Electrical Training Programs (96)

- Code & Standards (30)

- Electrical Maintenance (18)

- Mechanical HVAC (9)

- Safety (39)

- Mechanical Training Programs (75)

- Code & Standards (10)

- Electrical Safety (8)

- HVAC (19)

- Maintenance (19)

- Fluid Power (19)

- News (13)

- Onsite Training (2)

- Contractor Management (1)

- National Electric Code (9)

- OSHA Rules and Requirements (19)

- General Safety Tips (4)

- Industrial Safety (4)

- Plumbing Standards (3)

- Electrical Blueprint Reading (6)

- Natural Gas Safety (3)

- Ultrasonic Testing (1)

- PLC (11)

- High Voltage (4)

- Oil Analysis (2)

- Centrifugal Pumps (4)

- Variable Frequency Drives (6)

- Welding Safety (7)

- Chillers (3)

- Hazardous Locations (5)

- Confined Spaces (6)

- Infrared Thermography (2)

- NFPA 72 (4)

- Process Control Loops (3)

- Backflow Prevention (1)

- Electrical Grounding (2)

- Industrial Circuits (2)

- Boilers (5)

- Shaft Alignment (3)

- Hoisting and Rigging (3)

- Fiber Optics (5)

- Refrigeration (1)

- Arc Flash (8)

- NFPA 110 (1)

- Conveyor Systems (1)

- NFPA 70E (2)

- Process Instruments (1)

- Vibration Analysis (1)

- Industrial Generators (2)

- Life Safety Code (4)

- Electrical Switchgear (1)

- NFPA 79 (2)

- Steam Distribution Systems (2)

- Preventative Maintenance (2)

- Electrical Codes & Standards (5)

- Mechanical Maintenance (5)

- Mechanical Fluid Power (1)

- Electrical Safety (2)

Filter Blogs

- January 2026 (1)

- December 2025 (2)

- October 2025 (2)

- September 2025 (1)

- August 2025 (1)

- July 2025 (1)

- June 2025 (1)

- April 2025 (2)

- March 2025 (1)

- February 2025 (1)

- January 2025 (1)

- December 2024 (1)

- November 2024 (1)

- October 2024 (1)

- September 2024 (1)

- August 2023 (1)

- July 2023 (1)

- June 2023 (1)

- April 2023 (1)

- March 2023 (1)

- February 2023 (1)

- December 2022 (1)

- October 2022 (1)

- August 2022 (1)

- July 2022 (1)

- October 2019 (9)

- September 2019 (8)

- August 2019 (9)

- July 2019 (8)

- June 2019 (8)

- May 2019 (9)

- April 2019 (9)

- March 2019 (7)

- February 2019 (4)

- January 2019 (9)

- December 2018 (7)

- November 2018 (7)

- October 2018 (9)

- September 2018 (6)

- August 2018 (7)

- July 2018 (9)

- June 2018 (8)

- May 2018 (9)

- April 2018 (9)

- March 2018 (8)

- February 2018 (8)

- January 2018 (9)

- December 2017 (9)

- November 2017 (8)

- October 2017 (9)

- September 2017 (8)

- August 2017 (7)

- July 2017 (5)

- June 2017 (7)

- May 2017 (8)

- April 2017 (3)

- March 2017 (7)

- February 2017 (3)

- January 2017 (4)

- December 2016 (7)

- November 2016 (4)

- October 2016 (7)

- September 2016 (5)

- August 2016 (6)

- June 2016 (1)

- May 2016 (2)

- April 2016 (2)

- March 2016 (1)

- January 2016 (2)

- October 2015 (1)

- August 2015 (1)

- July 2015 (3)

- May 2015 (1)

- January 2015 (3)

- April 2014 (4)

Our Mission:

Deliver solutions to our clients (and their global workforce) designed for safety, productivity and profitability.

Our Vision:

Empowering clients and their employees to be safe and skilled.

NTT Training Inc. has been accredited by the Accrediting Council for Continuing Education & Training (ACCET).

Better Business Bureau

Better Business Bureau

A Training Division of ECPI University