- Electrical Training

- Safety

- Electrical Compliance

- Electrical Automation

- Electrical Maintenance

- Mechanical Training

- HVAC

- Codes and Standards

- Fluid Power

- Maintenance

- View All Training Programs

-

View All Electrical Safety Training ProgramsTop Electrical Safety Training Programs

- Arc Flash Electrical Safety [Based on NFPA 70E®]

- Electrical Safety: NFPA 70E Refresher

- Electrical Safety Awareness

- Electrical Safety Practical Skills for Switchgear

- Electrical Safety: Power Generation, Transmission & Distribution [based on OSHA 1910.269]

- Seguridad Eléctrica en el centro de trabajo, [Basado en el manual NFPA 70E® 2021]

- Electrical Safety, Operation and Maintenance for Medium Voltage (MV) Distribution Systems and Equipment

- Train-The-Observer: Electrical Safety Field Observer Training

Upcoming Training Programs- 03/24 - 03/25 : Centennial , CO Electrical Safety, Operation and Maintenance for Medium Voltage (MV) Distribution Systems and Equipment

- 04/06 - 04/07 : Live Online Training , CO Arc Flash Electrical Safety [Based on NFPA 70E®]

- 04/30 - 04/30 : Centennial , CO Electrical Safety Practical Skills for Switchgear

- 05/04 - 05/05 : Live Online Training , CO Arc Flash Electrical Safety [Based on NFPA 70E®]

- 06/01 - 06/02 : Live Online Training , CO Arc Flash Electrical Safety [Based on NFPA 70E®]

-

View All Electrical Electrical Compliance Training ProgramsTop Electrical Electrical Compliance Training Programs

- 2026 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

- New Jersey 1 Hour Electrical Law (License Requirement)

- Electrical Systems: SOARES Grounding & Bonding

- Electrical Systems: Hazardous Locations

- NEC® – Analysis of Changes 2020 with Practical Exercises

- NFPA 110® – Emergency & Standby Power Systems

- NFPA 70B® Standard Overview

- NFPA 70B Standard for Electrical Equipment Maintenance (8-hr for Maintenance Technicians)

- NFPA 72: National Fire Alarm & Signaling Code®

- NFPA 79® – Electrical Standard For Industrial Machinery®

- NICET I & II

- National Electrical Safety Code® [NESC]

- NEC® – Analysis of Changes 2023

- Connecticut Four Hour 2025 Electricians Continuing Education Course

- 2023 National Electrical Code® With 2023 Washington State’s Electrical Code Amendments (based on Washington Administrative Code 296-46B)

Upcoming Training Programs- 04/08 - 04/10 : Centennial , CO 2026 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

- 04/08 - 04/10 : Live Online Training , CO 2026 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

- 04/29 - 04/30 : Live Online Training , CO Electrical Systems: Hazardous Locations

- 05/06 - 05/08 : Live Online Training , CO 2026 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

- 06/03 - 06/05 : Live Online Training , CO 2026 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

-

View All Electrical Electrical Automation Training ProgramsTop Electrical Electrical Automation Training Programs

- Instrumentation & Process Control

- PLCs [Programmable Logic Controllers]: Automation Systems

- PLCs [Programmable Logic Controllers]: ControlLogix & RSLogix 5000

- PLCs [Programmable Logic Controllers]: Fundamentals

- PLCs [Programmable Logic Controllers]: Siemens Simatic S7

- Tuning DDC/Process Control Loops

- Variable Frequency Drives [VFD]

Upcoming Training Programs -

View All Electrical Electrical Maintenance Training ProgramsUpcoming Training Programs

- 03/31 - 04/01 : Centennial , CO Basics of Industrial Electricity

- 04/02 - 04/03 : Centennial , CO Electrical Motor Control Circuits: Troubleshooting

- 04/07 - 04/09 : Centennial , CO Fiber Optics

- 05/12 - 05/13 : Centennial , CO Basics of Industrial Electricity

- 05/14 - 05/15 : Centennial , CO Electrical Motor Control Circuits: Troubleshooting

-

View All Mechanical HVAC Training ProgramsTop Mechanical HVAC Training Programs

- Balancing of Water and Air Systems

- Boilers: An Operational Workshop

- HVAC: Brazing [Advanced]

- Air Conditioning & Refrigeration: Advanced

- HVAC: Air Conditioning & Refrigeration

- HVAC: Principles of Heating & Ventilation

- Chillers: Operation & Maintenance of Chilled Water Systems

- Steam Distribution Systems

- Water Treatment for Boilers and Chilled Water Systems

- EPA 608 Certification Exam Preparation & Proctoring

Upcoming Training Programs- 03/24 - 03/26 : Centennial , CO Chillers: Operation & Maintenance of Chilled Water Systems

- 05/19 - 05/21 : Centennial , CO Boilers: An Operational Workshop

- 06/08 - 06/10 : Centennial , CO HVAC: Air Conditioning & Refrigeration

- 06/11 - 06/11 : Centennial , CO EPA 608 Certification Exam Preparation & Proctoring

- 06/12 - 06/12 : Live Online Training , CO EPA 608 Certification Exam Preparation & Proctoring

- View All Mechanical Codes and Standards Training Programs

- View All Mechanical Fluid Power Training Programs

-

View All Mechanical Maintenance Training ProgramsUpcoming Training Programs

- 05/05 - 05/06 : Centennial , CO Electric Motors: Understanding & Troubleshooting

- 05/07 - 05/08 : Centennial , CO Shaft Alignment with Laser Technology

- 07/28 - 07/29 : Centennial , CO Electric Motors: Understanding & Troubleshooting

- 08/06 - 08/07 : Centennial , CO Shaft Alignment with Laser Technology

- 11/03 - 11/04 : Centennial , CO Electric Motors: Understanding & Troubleshooting

Select the following link if you would like to recover a report that has been previously deleted.

NTT Blog

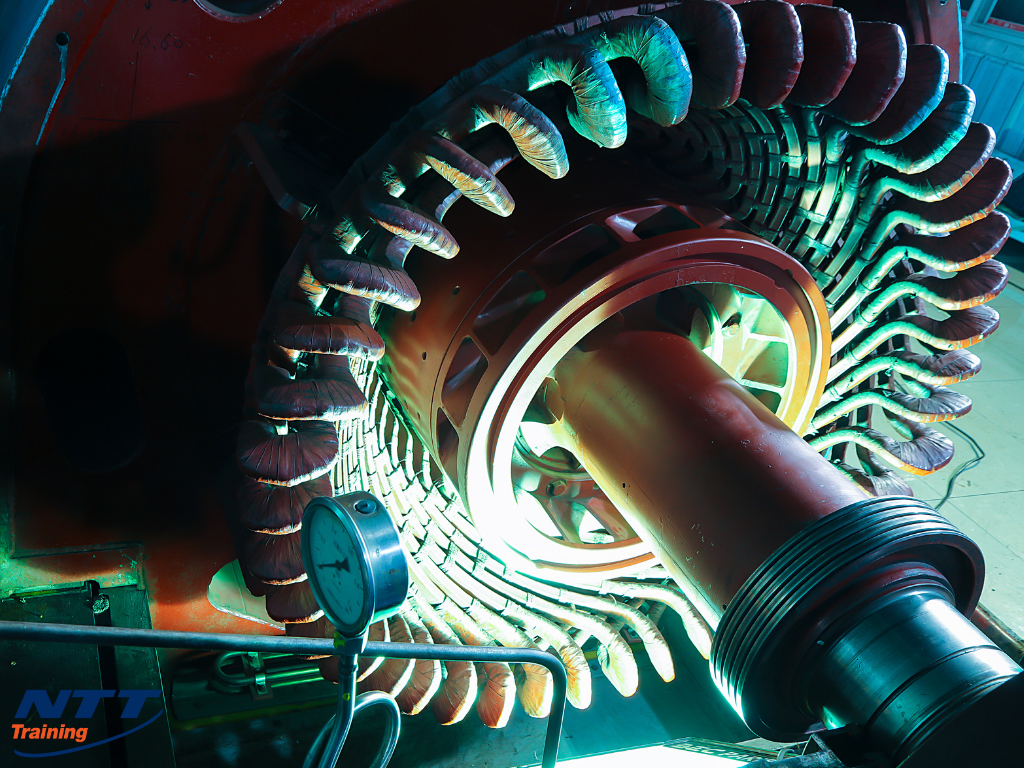

Industrial Generators: Safety Tips and Ideas to Keep Your Business Running

Industrial generators are employed to ensure that there is continuous supply of power in the event of failure of the main grid systems. Thus, these industrial equipment have the capacity to guarantee efficient performance of all industrial equipment, in case there are power outages. There are numerous generators for industrial application with different solutions to cater for the needs of an uninterrupted power supply and according to the types of need or emergency.

How do Industrial Generators Work?

Industrial generators are unique from residential models. These generators are designed to cope up with extreme usage for longer periods in less than ideal situations or conditions. Most industrial generator sizes range from 150hp to 4000hp engines with 20kW to 2500kW in output, the types of industrial generators also vary.

Industrial generators are robust equipment that are uniquely designed. Some run on diesel, gasoline and others run on Natural gas. Diesel generators are constantly used due to its durability and lower maintenance needs. A diesel engine running at 1800rpm can operate from 12,000 to 30,000 hours between major maintenance services.

As for the gas-powered engine, it requires servicing after 6,000 to 10,000 hours of running. Diesel dissipates relatively low heat compared to gasoline thus reducing wear and tear on the engine. Power generated by diesel generators can also be lower in costs because of its higher density, thus increasing efficiency.

Safety Tips to Consider When Working Around Industrial Generators

Workers should perform any installation, maintenance, and repairs in accordance with the manufacturers recommendations and instructions. Exhaust fumes produced by the generator are packed with poisonous gases like carbon monoxide that can threaten the life of your workers. It is therefore necessary that you properly install exhaust systems that provide sufficient ventilation to ensure that there is an unobstructed flow of ventilating and cooling air, as well as emissions directly away from the inhabited regions.

The employees are required to keep the areas around the generator clean and free from clutter as well as any combustible material that could be life threatening. They are also required to regularly inspect the generators and replace any defective parts within a timely manner.

It is required that the operating personnel remain vigilant at all times when working with the generators. When conducting repairs, your workers must not dismantle the unit while it is operational; hot or moving parts can cause harm. All the battery cables should be disconnected to avoid any mishap.

How can You Help Your Workers Prevent Dangerous Incidents?

Your employees should ensure that all power voltage supplies are turned off during the servicing or maintenance of the generator. The terminals, wires and cables should be properly covered and insulated, and all the workers cautioned from touching it with bare hands or while in contact with water. The above precaution will prevent your workers from electric shock.

When performing any installations or repairs, ensuring that the generator frame and its external conducting parts are properly grounded using an earthing wire help avert any accident. This should never be disconnected. Your employees must ensure to utilize cable, wiring and cord sets that are of the recommended capacity.

Tips Worth Repeating in the Industrial Workplace

Your workers should refrain from smoking in the vicinity of the equipment. Any oil or fuel spills around the generator, leakage from the unit’s fuels supply and systems, and presence of any combustible materials surrounding the generator will pose a high risk of explosion.

It is also a requirement to have a fire extinguisher within the vicinity. The fire extinguisher that operate on carbon tetra-chloride are strictly prohibited since they are packed with toxic fumes that can deteriorate/corrode the insulation and wiring of the generators.

Your workers ought to follow strict quarterly or semi-annual maintenance schedules to increase the reliability of the equipment. When your generators are exercised and inspected regularly, it continues to deliver consistent power output as per the expectations.

Employing a proactive maintenance on your generators will help prevent damages by detecting defects at an early stage allowing preventative action to be conducted within a timely manner.

Do Your Employees Need More Instruction on How to Be Safe Around Generators?

While the above tips are just generic guidelines that your workers can adhere to ensure safety when working around industrial generators it is a necessity that your employees understand the application and operation of industrial generators both on-site and standby.

At NTT, we offer NFPA approved Emergency & Standby Power Systems training program that conforms to the requirements needed for operation, maintenance and installation of standby/ on site industrial generators, batteries, transfer switches and UPS Systems. Contact us today and learn more.

Recent Blog Posts

- Expert Guide to NEC Compliance in New Jersey

- Why Electrical Safety Observer Training Is the Missing Link in NFPA 70E Compliance

- NEC: National Electric Code (2026 edition)

- NFPA 79: Electrical Standard for Industrial Machinery (2024 Edition)

- EPA 608 Certification and Training

- Categories

- Uncategorized (6)

- Electrical Training Programs (96)

- Code & Standards (30)

- Electrical Maintenance (18)

- Mechanical HVAC (9)

- Safety (39)

- Mechanical Training Programs (75)

- Code & Standards (10)

- Electrical Safety (8)

- HVAC (19)

- Maintenance (19)

- Fluid Power (19)

- News (13)

- Onsite Training (2)

- Contractor Management (1)

- National Electric Code (9)

- OSHA Rules and Requirements (19)

- General Safety Tips (4)

- Industrial Safety (4)

- Plumbing Standards (3)

- Electrical Blueprint Reading (6)

- Natural Gas Safety (3)

- Ultrasonic Testing (1)

- PLC (11)

- High Voltage (4)

- Oil Analysis (2)

- Centrifugal Pumps (4)

- Variable Frequency Drives (6)

- Welding Safety (7)

- Chillers (3)

- Hazardous Locations (5)

- Confined Spaces (6)

- Infrared Thermography (2)

- NFPA 72 (4)

- Process Control Loops (3)

- Backflow Prevention (1)

- Electrical Grounding (2)

- Industrial Circuits (2)

- Boilers (5)

- Shaft Alignment (3)

- Hoisting and Rigging (3)

- Fiber Optics (5)

- Refrigeration (1)

- Arc Flash (8)

- NFPA 110 (1)

- Conveyor Systems (1)

- NFPA 70E (2)

- Process Instruments (1)

- Vibration Analysis (1)

- Industrial Generators (2)

- Life Safety Code (4)

- Electrical Switchgear (1)

- NFPA 79 (2)

- Steam Distribution Systems (2)

- Preventative Maintenance (2)

- Electrical Codes & Standards (5)

- Mechanical Maintenance (5)

- Mechanical Fluid Power (1)

- Electrical Safety (2)

Filter Blogs

- January 2026 (1)

- December 2025 (2)

- October 2025 (2)

- September 2025 (1)

- August 2025 (1)

- July 2025 (1)

- June 2025 (1)

- April 2025 (2)

- March 2025 (1)

- February 2025 (1)

- January 2025 (1)

- December 2024 (1)

- November 2024 (1)

- October 2024 (1)

- September 2024 (1)

- August 2023 (1)

- July 2023 (1)

- June 2023 (1)

- April 2023 (1)

- March 2023 (1)

- February 2023 (1)

- December 2022 (1)

- October 2022 (1)

- August 2022 (1)

- July 2022 (1)

- October 2019 (9)

- September 2019 (8)

- August 2019 (9)

- July 2019 (8)

- June 2019 (8)

- May 2019 (9)

- April 2019 (9)

- March 2019 (7)

- February 2019 (4)

- January 2019 (9)

- December 2018 (7)

- November 2018 (7)

- October 2018 (9)

- September 2018 (6)

- August 2018 (7)

- July 2018 (9)

- June 2018 (8)

- May 2018 (9)

- April 2018 (9)

- March 2018 (8)

- February 2018 (8)

- January 2018 (9)

- December 2017 (9)

- November 2017 (8)

- October 2017 (9)

- September 2017 (8)

- August 2017 (7)

- July 2017 (5)

- June 2017 (7)

- May 2017 (8)

- April 2017 (3)

- March 2017 (7)

- February 2017 (3)

- January 2017 (4)

- December 2016 (7)

- November 2016 (4)

- October 2016 (7)

- September 2016 (5)

- August 2016 (6)

- June 2016 (1)

- May 2016 (2)

- April 2016 (2)

- March 2016 (1)

- January 2016 (2)

- October 2015 (1)

- August 2015 (1)

- July 2015 (3)

- May 2015 (1)

- January 2015 (3)

- April 2014 (4)

Our Mission:

Deliver solutions to our clients (and their global workforce) designed for safety, productivity and profitability.

Our Vision:

Empowering clients and their employees to be safe and skilled.

NTT Training Inc. has been accredited by the Accrediting Council for Continuing Education & Training (ACCET).

Better Business Bureau

Better Business Bureau

A Training Division of ECPI University