- Electrical Training

- Safety

- Electrical Compliance

- Electrical Automation

- Electrical Maintenance

- Mechanical Training

- HVAC

- Codes and Standards

- Fluid Power

- Maintenance

- View All Training Programs

-

View All Electrical Safety Training ProgramsTop Electrical Safety Training Programs

- Arc Flash Electrical Safety [Based on NFPA 70E®]

- Electrical Safety: NFPA 70E Refresher

- Electrical Safety Awareness

- Electrical Safety Practical Skills for Switchgear

- Electrical Safety: Power Generation, Transmission & Distribution [based on OSHA 1910.269]

- Seguridad Eléctrica en el centro de trabajo, [Basado en el manual NFPA 70E® 2021]

- Electrical Safety, Operation and Maintenance for Medium Voltage (MV) Distribution Systems and Equipment

- Train-The-Observer: Electrical Safety Field Observer Training

Upcoming Training Programs- 04/06 - 04/07 : Live Online Training , CO Arc Flash Electrical Safety [Based on NFPA 70E®]

- 04/30 - 04/30 : Centennial , CO Electrical Safety Practical Skills for Switchgear

- 05/04 - 05/05 : Live Online Training , CO Arc Flash Electrical Safety [Based on NFPA 70E®]

- 06/01 - 06/02 : Live Online Training , CO Arc Flash Electrical Safety [Based on NFPA 70E®]

- 06/23 - 06/24 : Centennial , CO Electrical Safety, Operation and Maintenance for Medium Voltage (MV) Distribution Systems and Equipment

-

View All Electrical Electrical Compliance Training ProgramsTop Electrical Electrical Compliance Training Programs

- 2026 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

- New Jersey 1 Hour Electrical Law (License Requirement)

- Electrical Systems: SOARES Grounding & Bonding

- Electrical Systems: Hazardous Locations

- NEC® – Analysis of Changes 2020 with Practical Exercises

- NFPA 110® – Emergency & Standby Power Systems

- NFPA 70B® Standard Overview

- NFPA 70B Standard for Electrical Equipment Maintenance (8-hr for Maintenance Technicians)

- NFPA 72: National Fire Alarm & Signaling Code®

- NFPA 79® – Electrical Standard For Industrial Machinery®

- NICET I & II

- National Electrical Safety Code® [NESC]

- NEC® – Analysis of Changes 2023

- Connecticut Four Hour 2025 Electricians Continuing Education Course

- 2023 National Electrical Code® With 2023 Washington State’s Electrical Code Amendments (based on Washington Administrative Code 296-46B)

Upcoming Training Programs- 04/08 - 04/10 : Centennial , CO 2026 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

- 04/08 - 04/10 : Live Online Training , CO 2026 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

- 04/29 - 04/30 : Live Online Training , CO Electrical Systems: Hazardous Locations

- 05/06 - 05/08 : Live Online Training , CO 2026 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

- 06/03 - 06/05 : Live Online Training , CO 2026 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

-

View All Electrical Electrical Automation Training ProgramsTop Electrical Electrical Automation Training Programs

- Instrumentation & Process Control

- PLCs [Programmable Logic Controllers]: Automation Systems

- PLCs [Programmable Logic Controllers]: ControlLogix & RSLogix 5000

- PLCs [Programmable Logic Controllers]: Fundamentals

- PLCs [Programmable Logic Controllers]: Siemens Simatic S7

- Tuning DDC/Process Control Loops

- Variable Frequency Drives [VFD]

Upcoming Training Programs -

View All Electrical Electrical Maintenance Training ProgramsUpcoming Training Programs

- 03/31 - 04/01 : Centennial , CO Basics of Industrial Electricity

- 04/02 - 04/03 : Centennial , CO Electrical Motor Control Circuits: Troubleshooting

- 04/07 - 04/09 : Centennial , CO Fiber Optics

- 05/12 - 05/13 : Centennial , CO Basics of Industrial Electricity

- 05/14 - 05/15 : Centennial , CO Electrical Motor Control Circuits: Troubleshooting

-

View All Mechanical HVAC Training ProgramsTop Mechanical HVAC Training Programs

- Balancing of Water and Air Systems

- Boilers: An Operational Workshop

- HVAC: Brazing [Advanced]

- Air Conditioning & Refrigeration: Advanced

- HVAC: Air Conditioning & Refrigeration

- HVAC: Principles of Heating & Ventilation

- Chillers: Operation & Maintenance of Chilled Water Systems

- Steam Distribution Systems

- Water Treatment for Boilers and Chilled Water Systems

- EPA 608 Certification Exam Preparation & Proctoring

Upcoming Training Programs- 05/19 - 05/21 : Centennial , CO Boilers: An Operational Workshop

- 06/08 - 06/10 : Centennial , CO HVAC: Air Conditioning & Refrigeration

- 06/11 - 06/11 : Centennial , CO EPA 608 Certification Exam Preparation & Proctoring

- 06/12 - 06/12 : Live Online Training , CO EPA 608 Certification Exam Preparation & Proctoring

- 07/07 - 07/09 : Centennial , CO Chillers: Operation & Maintenance of Chilled Water Systems

- View All Mechanical Codes and Standards Training Programs

- View All Mechanical Fluid Power Training Programs

-

View All Mechanical Maintenance Training ProgramsUpcoming Training Programs

- 05/05 - 05/06 : Centennial , CO Electric Motors: Understanding & Troubleshooting

- 05/07 - 05/08 : Centennial , CO Shaft Alignment with Laser Technology

- 07/28 - 07/29 : Centennial , CO Electric Motors: Understanding & Troubleshooting

- 08/06 - 08/07 : Centennial , CO Shaft Alignment with Laser Technology

- 11/03 - 11/04 : Centennial , CO Electric Motors: Understanding & Troubleshooting

Select the following link if you would like to recover a report that has been previously deleted.

NTT Blog

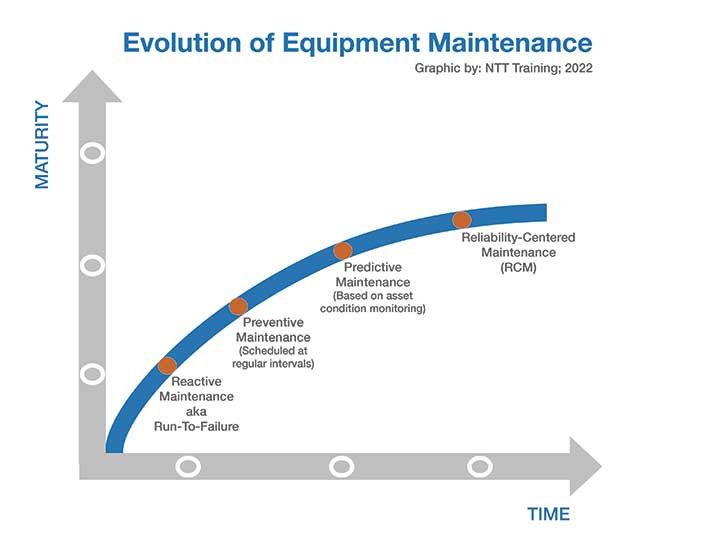

Maintenance Strategies: From Reactive to Reliability-Centered

Maintenance Strategies – Which stage best describes your current situation?

“We spent XX dollars on maintenance last quarter, but how much did we really improve our overall operations?”

Sound familiar? As threats of a recession and high inflation continue to dominate national headlines, the question remains – what can you do now to help address these concerns at your company?

One way is to first identify where you fall on the spectrum of maintenance strategies. In our next blog, we will further investigate how you can implement small changes to progress forward along this spectrum for a larger payback.

Stage 1: Reactive Maintenance aka Run-To-Failure

What: Fixing a tool or a part of a machine at the time of breakage; also known as run-to-failure

Reactive maintenance is our first line of defense to put out immediate fires and return to operational status. This methodology dates back to the Neothilic Age, about 12,000 years ago, and was more formally documented during the Industrial Revolution (1760 – 1840) in Europe, which first introduced us to the machine age and created the need for machine maintenance workers. This tried and true methodology is still used today to keep upfront maintenance costs low but can negatively affect budgets and productivity in the long run.

The cost of unplanned downtime was approximately $250,000 per hour, at an average of more than $2 million per downtime event.

Increasing repair costs for parts and labor equates to a 30 – 40% higher cost expectancy for reactive maintenance versus predictive maintenance strategies.

Stage 2: Preventive Maintenance

What: Fixing a part of a machine right before it fails

Preventive maintenance is the first step to taking a more proactive approach to maintenance using time-based and interval-based maintenance techniques. One of the first mentions in history for preventative maintenance dates back to the German DUV, founded in 1872, that loosely translates to the Steam Boiler Monitoring Association, to preserve the life of factory workers and keep factories operational. This strategy can be beneficial for equipment that is essential to your operations, but often times does not include the metrics needed to implement a more predictable maintenance schedule.

When preventative maintenance strategies are used instead of reactive, manufacturing firms identified a 12% – 18% overall cost savings.

Preventive maintenance costs $13/hour per year, while predictive maintenance costs $9/hour per year according to Ulbert’s report The Difference Between Predictive Maintenance and Preventive Maintenance.

Stage 3: Predictive Maintenance

What: Fixing a part of a machine in relation to the actual condition of the equipment and the usage pattern

Predictive maintenance uses condition monitoring to predict machine failure based on the actual condition and usage of the machine, and not a preset schedule. It is linked back to

C.H. Waddington, a British epidemiologist, who in 1943 discovered predictive patterns in aircraft performance based on the condition of the airplanes and their usage while inspecting the Royal Air Force Coastal Command 502 Squadron. Predictive maintenance strategies can increase the operational life of equipment and improve worker and environmental safety, but the savings potential is not always readily realized by management.

The U.S. Department of Energy’s O&M Best Practices Guide identified a 10-fold return-on-investment for industrial manufacturing when predictive maintenance strategies are used.

Stage 4: Reliability-Centered Maintenance (RCM)

What: Fixing a part of machine based on a data-driven system that assesses each components’ maintenance needs based on the design life cycle of the machine with the minimum amount of maintenance required

This process is based on the posture that all equipment in a facility is not of equal importance and involves investigating failures to determine the best maintenance schedule to maximize equipment efficiency. In an effort to create more reliability for passenger safety, Stanley Nowlan and Howard Heap first published the concept of RCM, in a study commissioned to United Airlines from the US Department of Defense. RCM is a highly efficient maintenance practice but is also one of the most expensive strategies to implement.

24% of manufacturing companies are currently using RCM strategies, according to the 2021 Plant Engineering’s annual Maintenance Study.

Now that we’ve established a common foundation for our discussion, we can dive into the practical steps and challenges maintenance managers and planners have. In the meantime, what is your biggest challenge regarding maintenance schedules and practices? Share your questions and challenges and we’ll do our best to address them in our series.

Recent Blog Posts

- Expert Guide to NEC Compliance in New Jersey

- Why Electrical Safety Observer Training Is the Missing Link in NFPA 70E Compliance

- NEC: National Electric Code (2026 edition)

- NFPA 79: Electrical Standard for Industrial Machinery (2024 Edition)

- EPA 608 Certification and Training

- Categories

- Uncategorized (6)

- Electrical Training Programs (96)

- Code & Standards (30)

- Electrical Maintenance (18)

- Mechanical HVAC (9)

- Safety (39)

- Mechanical Training Programs (75)

- Code & Standards (10)

- Electrical Safety (8)

- HVAC (19)

- Maintenance (19)

- Fluid Power (19)

- News (13)

- Onsite Training (2)

- Contractor Management (1)

- National Electric Code (9)

- OSHA Rules and Requirements (19)

- General Safety Tips (4)

- Industrial Safety (4)

- Plumbing Standards (3)

- Electrical Blueprint Reading (6)

- Natural Gas Safety (3)

- Ultrasonic Testing (1)

- PLC (11)

- High Voltage (4)

- Oil Analysis (2)

- Centrifugal Pumps (4)

- Variable Frequency Drives (6)

- Welding Safety (7)

- Chillers (3)

- Hazardous Locations (5)

- Confined Spaces (6)

- Infrared Thermography (2)

- NFPA 72 (4)

- Process Control Loops (3)

- Backflow Prevention (1)

- Electrical Grounding (2)

- Industrial Circuits (2)

- Boilers (5)

- Shaft Alignment (3)

- Hoisting and Rigging (3)

- Fiber Optics (5)

- Refrigeration (1)

- Arc Flash (8)

- NFPA 110 (1)

- Conveyor Systems (1)

- NFPA 70E (2)

- Process Instruments (1)

- Vibration Analysis (1)

- Industrial Generators (2)

- Life Safety Code (4)

- Electrical Switchgear (1)

- NFPA 79 (2)

- Steam Distribution Systems (2)

- Preventative Maintenance (2)

- Electrical Codes & Standards (5)

- Mechanical Maintenance (5)

- Mechanical Fluid Power (1)

- Electrical Safety (2)

Filter Blogs

- January 2026 (1)

- December 2025 (2)

- October 2025 (2)

- September 2025 (1)

- August 2025 (1)

- July 2025 (1)

- June 2025 (1)

- April 2025 (2)

- March 2025 (1)

- February 2025 (1)

- January 2025 (1)

- December 2024 (1)

- November 2024 (1)

- October 2024 (1)

- September 2024 (1)

- August 2023 (1)

- July 2023 (1)

- June 2023 (1)

- April 2023 (1)

- March 2023 (1)

- February 2023 (1)

- December 2022 (1)

- October 2022 (1)

- August 2022 (1)

- July 2022 (1)

- October 2019 (9)

- September 2019 (8)

- August 2019 (9)

- July 2019 (8)

- June 2019 (8)

- May 2019 (9)

- April 2019 (9)

- March 2019 (7)

- February 2019 (4)

- January 2019 (9)

- December 2018 (7)

- November 2018 (7)

- October 2018 (9)

- September 2018 (6)

- August 2018 (7)

- July 2018 (9)

- June 2018 (8)

- May 2018 (9)

- April 2018 (9)

- March 2018 (8)

- February 2018 (8)

- January 2018 (9)

- December 2017 (9)

- November 2017 (8)

- October 2017 (9)

- September 2017 (8)

- August 2017 (7)

- July 2017 (5)

- June 2017 (7)

- May 2017 (8)

- April 2017 (3)

- March 2017 (7)

- February 2017 (3)

- January 2017 (4)

- December 2016 (7)

- November 2016 (4)

- October 2016 (7)

- September 2016 (5)

- August 2016 (6)

- June 2016 (1)

- May 2016 (2)

- April 2016 (2)

- March 2016 (1)

- January 2016 (2)

- October 2015 (1)

- August 2015 (1)

- July 2015 (3)

- May 2015 (1)

- January 2015 (3)

- April 2014 (4)

Our Mission:

Deliver solutions to our clients (and their global workforce) designed for safety, productivity and profitability.

Our Vision:

Empowering clients and their employees to be safe and skilled.

NTT Training Inc. has been accredited by the Accrediting Council for Continuing Education & Training (ACCET).

Better Business Bureau

Better Business Bureau

A Training Division of ECPI University