- Electrical Training

- Safety

- Electrical Compliance

- Electrical Automation

- Electrical Maintenance

- Mechanical Training

- HVAC

- Codes and Standards

- Fluid Power

- Maintenance

- View All Training Programs

-

View All Electrical Safety Training ProgramsTop Electrical Safety Training Programs

- Arc Flash Electrical Safety [Based on NFPA 70E®]

- Electrical Safety: NFPA 70E Refresher

- Electrical Safety Awareness

- Electrical Safety Practical Skills for Switchgear

- Electrical Safety: Power Generation, Transmission & Distribution [based on OSHA 1910.269]

- Seguridad Eléctrica en el centro de trabajo, [Basado en el manual NFPA 70E® 2021]

- Electrical Safety, Operation and Maintenance for Medium Voltage (MV) Distribution Systems and Equipment

- Train-The-Observer: Electrical Safety Field Observer Training

Upcoming Training Programs- 04/06 - 04/07 : Live Online Training , CO Arc Flash Electrical Safety [Based on NFPA 70E®]

- 04/30 - 04/30 : Centennial , CO Electrical Safety Practical Skills for Switchgear

- 05/04 - 05/05 : Live Online Training , CO Arc Flash Electrical Safety [Based on NFPA 70E®]

- 06/01 - 06/02 : Live Online Training , CO Arc Flash Electrical Safety [Based on NFPA 70E®]

- 06/23 - 06/24 : Centennial , CO Electrical Safety, Operation and Maintenance for Medium Voltage (MV) Distribution Systems and Equipment

-

View All Electrical Electrical Compliance Training ProgramsTop Electrical Electrical Compliance Training Programs

- 2026 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

- New Jersey 1 Hour Electrical Law (License Requirement)

- Electrical Systems: SOARES Grounding & Bonding

- Electrical Systems: Hazardous Locations

- NEC® – Analysis of Changes 2020 with Practical Exercises

- NFPA 110® – Emergency & Standby Power Systems

- NFPA 70B® Standard Overview

- NFPA 70B Standard for Electrical Equipment Maintenance (8-hr for Maintenance Technicians)

- NFPA 72: National Fire Alarm & Signaling Code®

- NFPA 79® – Electrical Standard For Industrial Machinery®

- NICET I & II

- National Electrical Safety Code® [NESC]

- NEC® – Analysis of Changes 2023

- Connecticut Four Hour 2025 Electricians Continuing Education Course

- 2023 National Electrical Code® With 2023 Washington State’s Electrical Code Amendments (based on Washington Administrative Code 296-46B)

Upcoming Training Programs- 04/08 - 04/10 : Centennial , CO 2026 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

- 04/08 - 04/10 : Live Online Training , CO 2026 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

- 04/29 - 04/30 : Live Online Training , CO Electrical Systems: Hazardous Locations

- 05/06 - 05/08 : Live Online Training , CO 2026 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

- 06/03 - 06/05 : Live Online Training , CO 2026 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

-

View All Electrical Electrical Automation Training ProgramsTop Electrical Electrical Automation Training Programs

- Instrumentation & Process Control

- PLCs [Programmable Logic Controllers]: Automation Systems

- PLCs [Programmable Logic Controllers]: ControlLogix & RSLogix 5000

- PLCs [Programmable Logic Controllers]: Fundamentals

- PLCs [Programmable Logic Controllers]: Siemens Simatic S7

- Tuning DDC/Process Control Loops

- Variable Frequency Drives [VFD]

Upcoming Training Programs -

View All Electrical Electrical Maintenance Training ProgramsUpcoming Training Programs

- 04/02 - 04/03 : Centennial , CO Electrical Motor Control Circuits: Troubleshooting

- 04/07 - 04/09 : Centennial , CO Fiber Optics

- 05/12 - 05/13 : Centennial , CO Basics of Industrial Electricity

- 05/14 - 05/15 : Centennial , CO Electrical Motor Control Circuits: Troubleshooting

- 07/07 - 07/09 : Centennial , CO Fiber Optics

-

View All Mechanical HVAC Training ProgramsTop Mechanical HVAC Training Programs

- Balancing of Water and Air Systems

- Boilers: An Operational Workshop

- HVAC: Brazing [Advanced]

- Air Conditioning & Refrigeration: Advanced

- HVAC: Air Conditioning & Refrigeration

- HVAC: Principles of Heating & Ventilation

- Chillers: Operation & Maintenance of Chilled Water Systems

- Steam Distribution Systems

- Water Treatment for Boilers and Chilled Water Systems

- EPA 608 Certification Exam Preparation & Proctoring

Upcoming Training Programs- 05/19 - 05/21 : Centennial , CO Boilers: An Operational Workshop

- 06/08 - 06/10 : Centennial , CO HVAC: Air Conditioning & Refrigeration

- 06/11 - 06/11 : Centennial , CO EPA 608 Certification Exam Preparation & Proctoring

- 06/12 - 06/12 : Live Online Training , CO EPA 608 Certification Exam Preparation & Proctoring

- 07/07 - 07/09 : Centennial , CO Chillers: Operation & Maintenance of Chilled Water Systems

- View All Mechanical Codes and Standards Training Programs

- View All Mechanical Fluid Power Training Programs

-

View All Mechanical Maintenance Training ProgramsUpcoming Training Programs

- 05/05 - 05/06 : Centennial , CO Electric Motors: Understanding & Troubleshooting

- 05/07 - 05/08 : Centennial , CO Shaft Alignment with Laser Technology

- 07/28 - 07/29 : Centennial , CO Electric Motors: Understanding & Troubleshooting

- 08/06 - 08/07 : Centennial , CO Shaft Alignment with Laser Technology

- 11/03 - 11/04 : Centennial , CO Electric Motors: Understanding & Troubleshooting

Select the following link if you would like to recover a report that has been previously deleted.

NTT Blog

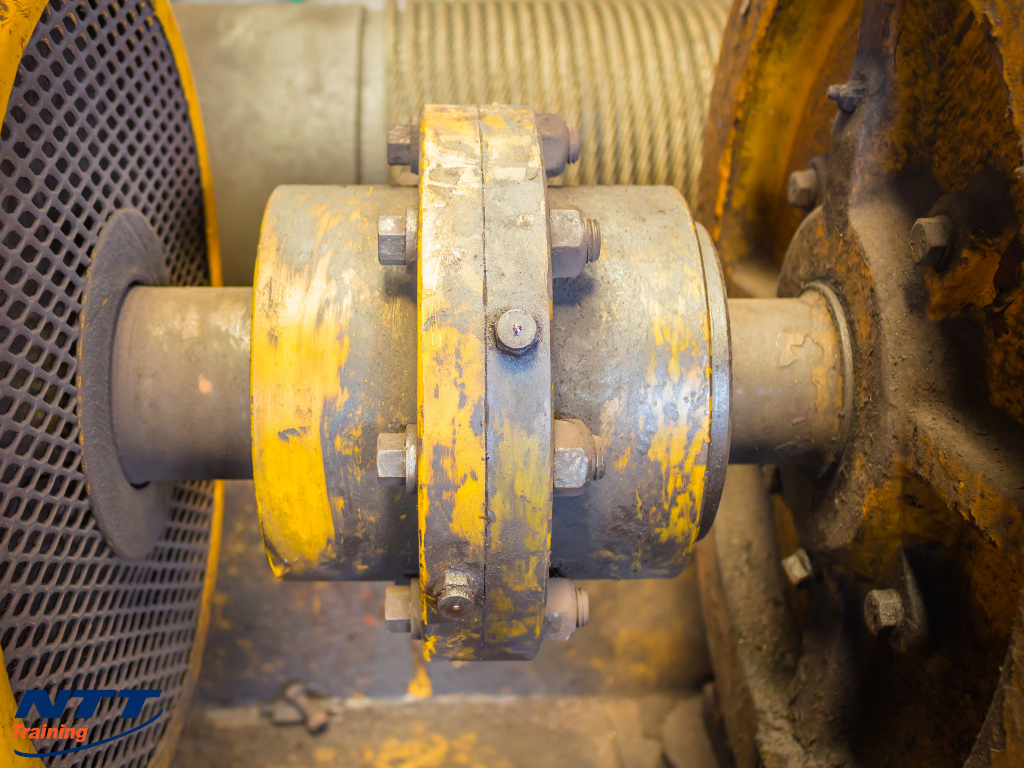

Shaft Alignment Basics Your Team Needs to Know

Machinery is the pillar to outcome realization and profit making in any production and manufacturing industry. This fact always calls for an up-to-date and efficient process. Maintaining good shaft alignment is therefore crucial to productivity and profit realization. For your company to achieve this, your team should be tech savvy when it comes to shaft alignment.

What are Some of the Basics to Shaft Alignment with a Laser?

Precise alignment is achieved when the center lines of rotation of two shafts essentially are collinear with each other.

Opposed to the conventional mechanical methods, laser alignment of shafts in rotating machinery is simple and more accurate. Through the use of sensors (PSD’s and IPS’) and small measuring units, design and implementation of actual shaft adjustment is actualized.

Thus, laser shaft alignment is the best technology when looking to increase the precision and efficiency of your team. It offers a long term benefit encompassed under diagnosis, repair, installation, and maintenance.

Through the use of laser beams rather than steel bars, there is no indicator bag sag and hysteresis, low resolution, reading errors and shaft axial play that can affect readings.

Also, PSD provides high resolution while minimizing human errors through PSD signal processing for the readout system achieved through laser beam transmission, detection, and pre-calibration units. In the long-run, accurate shaft alignment will increase the life of bearings, seals, and couplings.

Why is Shaft Alignment Important?

Maintaining correct shaft alignment on your machinery directly affects the rate of company productivity and profits through the smooth running of operations.

Being either a manufacturing or production industry, downtimes are intolerable. To avoid them, all the rotating machinery should be maintained at peak operation. Your technical team should always have the quickest and most accurate ways of conducting the maintenance.

This is how shaft alignment helps workers do their jobs more efficiently.

Improved Machine Reliability and Productivity

The ability of your machines to produce at the required time and the right quantities is indispensable. Maintaining good shaft alignment cuts on downtime experiences while saving on time that would otherwise be used on conducting repairs.

Reduced Power Consumption and Part Failures

The transmission of rotary motion to the driven parts of your machines from their motors involves power transmission. In case of any misalignment, some of this power is used to supply energies to sliding velocities that cause wear and tear on bearings, seals, and couplings.

Minimizes Installation and Repair Time

Mainly, horizontal corrections are made after vertical tolerances are satisfied, however, at times there is a need for further vertical adjustment after horizontal adjustments are made ending up in time wastage.

What are the Benefits to Sending Workers for Formal Training?

Being a company owner, it is important to have a competent team with up-to-date laser alignment training. This not only increases their skill but also the productivity of your company.

Proper training does not just focus on shaft alignment but on its diversity as a whole. Let us consider;

- What happened before the alignment condition is met?

- What do you do in a post-alignment mishap?

- Do you understand what the machine you are aligning is telling you?

Diagnosis for misalignment, resolving the problem and mastering proper alignment procedures are vital of the process. Formal training enhances the recognition of your technicians for the overall quality assurance.

Think About the Future of Your Workers and Your Facility

Do you want top-notch training for your shaft alignment team? NTT Inc. is the solution. To know more about our online and on-site training, contact NTT Inc. today for more information!

NTT Inc. has its training accredited by the Accrediting Council for Continuing Education and Training(ACCET). We offer a comprehensive laser training experience, serving the interests of agencies, companies and the public.

Recent Blog Posts

- Expert Guide to NEC Compliance in New Jersey

- Why Electrical Safety Observer Training Is the Missing Link in NFPA 70E Compliance

- NEC: National Electric Code (2026 edition)

- NFPA 79: Electrical Standard for Industrial Machinery (2024 Edition)

- EPA 608 Certification and Training

- Categories

- Uncategorized (6)

- Electrical Training Programs (96)

- Code & Standards (30)

- Electrical Maintenance (18)

- Mechanical HVAC (9)

- Safety (39)

- Mechanical Training Programs (75)

- Code & Standards (10)

- Electrical Safety (8)

- HVAC (19)

- Maintenance (19)

- Fluid Power (19)

- News (13)

- Onsite Training (2)

- Contractor Management (1)

- National Electric Code (9)

- OSHA Rules and Requirements (19)

- General Safety Tips (4)

- Industrial Safety (4)

- Plumbing Standards (3)

- Electrical Blueprint Reading (6)

- Natural Gas Safety (3)

- Ultrasonic Testing (1)

- PLC (11)

- High Voltage (4)

- Oil Analysis (2)

- Centrifugal Pumps (4)

- Variable Frequency Drives (6)

- Welding Safety (7)

- Chillers (3)

- Hazardous Locations (5)

- Confined Spaces (6)

- Infrared Thermography (2)

- NFPA 72 (4)

- Process Control Loops (3)

- Backflow Prevention (1)

- Electrical Grounding (2)

- Industrial Circuits (2)

- Boilers (5)

- Shaft Alignment (3)

- Hoisting and Rigging (3)

- Fiber Optics (5)

- Refrigeration (1)

- Arc Flash (8)

- NFPA 110 (1)

- Conveyor Systems (1)

- NFPA 70E (2)

- Process Instruments (1)

- Vibration Analysis (1)

- Industrial Generators (2)

- Life Safety Code (4)

- Electrical Switchgear (1)

- NFPA 79 (2)

- Steam Distribution Systems (2)

- Preventative Maintenance (2)

- Electrical Codes & Standards (5)

- Mechanical Maintenance (5)

- Mechanical Fluid Power (1)

- Electrical Safety (2)

Filter Blogs

- January 2026 (1)

- December 2025 (2)

- October 2025 (2)

- September 2025 (1)

- August 2025 (1)

- July 2025 (1)

- June 2025 (1)

- April 2025 (2)

- March 2025 (1)

- February 2025 (1)

- January 2025 (1)

- December 2024 (1)

- November 2024 (1)

- October 2024 (1)

- September 2024 (1)

- August 2023 (1)

- July 2023 (1)

- June 2023 (1)

- April 2023 (1)

- March 2023 (1)

- February 2023 (1)

- December 2022 (1)

- October 2022 (1)

- August 2022 (1)

- July 2022 (1)

- October 2019 (9)

- September 2019 (8)

- August 2019 (9)

- July 2019 (8)

- June 2019 (8)

- May 2019 (9)

- April 2019 (9)

- March 2019 (7)

- February 2019 (4)

- January 2019 (9)

- December 2018 (7)

- November 2018 (7)

- October 2018 (9)

- September 2018 (6)

- August 2018 (7)

- July 2018 (9)

- June 2018 (8)

- May 2018 (9)

- April 2018 (9)

- March 2018 (8)

- February 2018 (8)

- January 2018 (9)

- December 2017 (9)

- November 2017 (8)

- October 2017 (9)

- September 2017 (8)

- August 2017 (7)

- July 2017 (5)

- June 2017 (7)

- May 2017 (8)

- April 2017 (3)

- March 2017 (7)

- February 2017 (3)

- January 2017 (4)

- December 2016 (7)

- November 2016 (4)

- October 2016 (7)

- September 2016 (5)

- August 2016 (6)

- June 2016 (1)

- May 2016 (2)

- April 2016 (2)

- March 2016 (1)

- January 2016 (2)

- October 2015 (1)

- August 2015 (1)

- July 2015 (3)

- May 2015 (1)

- January 2015 (3)

- April 2014 (4)

Our Mission:

Deliver solutions to our clients (and their global workforce) designed for safety, productivity and profitability.

Our Vision:

Empowering clients and their employees to be safe and skilled.

NTT Training Inc. has been accredited by the Accrediting Council for Continuing Education & Training (ACCET).

Better Business Bureau

Better Business Bureau

A Training Division of ECPI University