- Electrical Training

- Safety

- Electrical Compliance

- Electrical Automation

- Electrical Maintenance

- Mechanical Training

- HVAC

- Codes and Standards

- Fluid Power

- Maintenance

- View All Training Programs

-

View All Electrical Safety Training ProgramsTop Electrical Safety Training Programs

- Arc Flash Electrical Safety [Based on NFPA 70E®]

- Electrical Safety: NFPA 70E Refresher

- Electrical Safety Awareness

- Electrical Safety Practical Skills for Switchgear

- Electrical Safety: Power Generation, Transmission & Distribution [based on OSHA 1910.269]

- Seguridad Eléctrica en el centro de trabajo, [Basado en el manual NFPA 70E® 2021]

- Electrical Safety, Operation and Maintenance for Medium Voltage (MV) Distribution Systems and Equipment

Upcoming Training Programs- 08/18 - 08/19 : Reno , NV Arc Flash Electrical Safety [Based on NFPA 70E®]

- 09/08 - 09/09 : Live Online Training , CO Arc Flash Electrical Safety [Based on NFPA 70E®]

- 09/11 - 09/11 : Live Online Training , CO Electrical Safety: Power Generation, Transmission & Distribution [based on OSHA 1910.269]

- 09/15 - 09/16 : Centennial , CO Arc Flash Electrical Safety [Based on NFPA 70E®]

- 10/06 - 10/07 : Live Online Training , CO Arc Flash Electrical Safety [Based on NFPA 70E®]

-

View All Electrical Electrical Compliance Training ProgramsTop Electrical Electrical Compliance Training Programs

- 2023 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

- Electrical Systems: SOARES Grounding & Bonding

- Electrical Systems: Hazardous Locations

- NEC® – Analysis of Changes 2020 with Practical Exercises

- NFPA 110® – Emergency & Standby Power Systems

- NFPA 70B® Standard Overview

- NFPA 70B Standard for Electrical Equipment Maintenance (8-hr for Maintenance Technicians)

- NFPA 72: National Fire Alarm & Signaling Code®

- 2021 NFPA 79® – Electrical Standard For Industrial Machinery®

- NICET I & II

- National Electrical Safety Code® [NESC]

- NEC® – Analysis of Changes 2023

- Connecticut Four Hour 2025 Electricians Continuing Education Course

- 2023 National Electrical Code® With 2023 Washington State’s Electrical Code Amendments (based on Washington Administrative Code 296-46B)

Upcoming Training Programs- 08/20 - 08/22 : Reno , NV 2023 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

- 09/08 - 09/09 : Live Online Training , CO Electrical Systems: SOARES Grounding & Bonding

- 09/10 - 09/12 : Live Online Training , CO 2023 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

- 09/10 - 09/11 : Live Online Training , CO Electrical Systems: Hazardous Locations

- 09/10 - 09/11 : Live Online Training , CO NICET I & II

-

View All Electrical Electrical Automation Training ProgramsTop Electrical Electrical Automation Training Programs

- Instrumentation & Process Control

- PLCs [Programmable Logic Controllers]: Automation Systems

- PLCs [Programmable Logic Controllers]: ControlLogix & RSLogix 5000

- PLCs [Programmable Logic Controllers]: Fundamentals

- PLCs [Programmable Logic Controllers]: Siemens Simatic S7

- Tuning DDC/Process Control Loops

- Variable Frequency Drives [VFD]

-

View All Electrical Electrical Maintenance Training ProgramsUpcoming Training Programs

- 08/12 - 08/13 : Seattle , WA Basics of Industrial Electricity

- 08/14 - 08/15 : Seattle , WA Electrical Motor Control Circuits: Troubleshooting

- 08/26 - 08/27 : Sacramento , CA Basics of Industrial Electricity

- 08/28 - 08/29 : Sacramento , CA Electrical Motor Control Circuits: Troubleshooting

- 09/09 - 09/10 : Centennial , CO Electrical Print Reading: Blueprints & Schematics

-

View All Mechanical HVAC Training ProgramsTop Mechanical HVAC Training Programs

- Balancing of Water and Air Systems

- Boilers: An Operational Workshop

- HVAC: Brazing [Advanced]

- Air Conditioning & Refrigeration: Advanced

- HVAC: Air Conditioning & Refrigeration

- HVAC: Principles of Heating & Ventilation

- Chillers: Operation & Maintenance of Chilled Water Systems

- Steam Distribution Systems

- Water Treatment for Boilers and Chilled Water Systems

Upcoming Training Programs- 08/12 - 08/14 : Houston , TX HVAC: Air Conditioning & Refrigeration

- 08/21 - 08/22 : Live Online Training , CO Boilers: An Operational Workshop

- 08/26 - 08/27 : Live Online Training , CO HVAC: Air Conditioning & Refrigeration

- 08/27 - 08/28 : Live Online Training , CO Chillers: Operation & Maintenance of Chilled Water Systems

- 10/06 - 10/08 : Centennial , CO HVAC: Air Conditioning & Refrigeration

- View All Mechanical Codes and Standards Training Programs

- View All Mechanical Fluid Power Training Programs

-

View All Mechanical Maintenance Training ProgramsUpcoming Training Programs

Select the following link if you would like to recover a report that has been previously deleted.

NTT Blog

Troubleshooting Electric Motors with Confidence: Training Your Employees Need

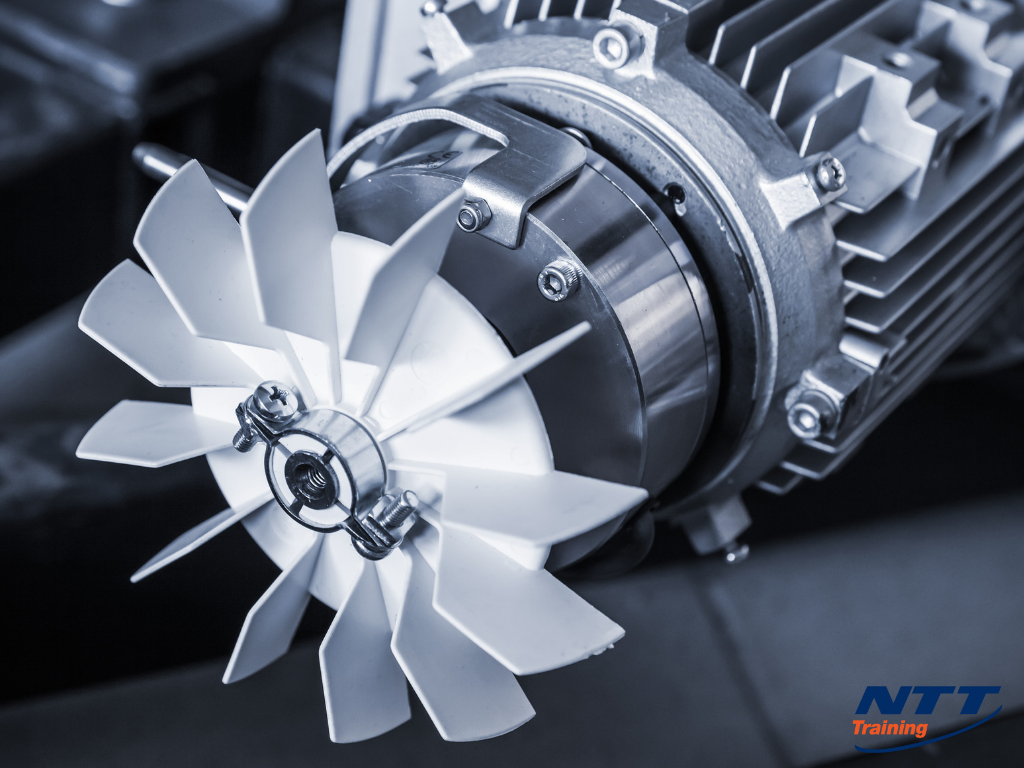

Electric motors are everywhere. From transportation to manufacturing, electric motors are an essential part of modern life. Businesses that depend on the machinery of all sizes and purposes need an expert on-staff to keep production lines running strong. What is an electric motor and how is it used in the business world? What are some basic troubleshooting tips your maintenance staff need to know? Why should your employees be trained on electric motor troubleshooting?

The Basics of Electric Motors

Electric motors are machines that turn electrical energy into mechanical energy. They can use either AC (alternating current) or DC (direct current) as a power source. The type of power the machine receives often defines its use. Direct current is generally weaker or stored energy, so it’s best applied to short-term solutions like power tools, vehicles, and portable devices. Alternating current comes directly from generators and power grids. AC-powered motors are used to run manufacturing lines and industrial pumps.

Today’s businesses use all types of electric motors to help them produce goods, move inventory, and provide services to their clients.

- Automated production lines in manufacturing facilities

- Electric forklifts

- Heavy duty tools like lathes, drill presses, and saws

- Handheld saws, drills, and drivers

- Blowers and high-powered fans

- Pumping systems

- Compressors and turbines

Electric motors aren’t just used in the industrial world. Motors are found in everything from electric landscaping tools to medical facilities. These flexible machines have almost endless applications in modern business.

Tips for Troubleshooting Your Electric Motor

A malfunctioning electric motor makes it difficult to meet deadlines and endangers profits. Use these tips to get your motor back in working order before you call a repairperson.

- Turn the machine off completely before attempting to diagnose any issues. This will help you avoid injury.

- Look around the outside of the motor. Do you see any obvious signs of damage like missing pieces or bent parts?

- Check for dirt or oil that creates clogs and keeps machine mechanisms from working properly.

- Look at the center of the motor. Do you see any dark spots on the paint? This is a sign of excessive heat damage. It is also possible to smell heat damaged metal.

- Make sure there are no sources of moisture that could be causing damage to your machinery. Look for signs of vapor or liquid around your device.

- Look for disconnected or damaged bearings. These are usually found at the ends of the motor.

- Inspect the fan blades to ensure nothing is stopping their rotation.

If you still aren’t able to find the problem after performing these steps, you may need to call a professional to diagnose your machine.

Benefits of Training Your Staff in Electric Motor Troubleshooting

Every minute your machine is down costs you potential profit. Ensure your business continues to run strong by training your employees in the basics of electric motor troubleshooting. Why should you invest in this training?

- Lower repair bills. Instead of calling an expert every time your machines go down, your staff member can diagnose and repair most smaller issues. Over time, this will save you a significant amount of money on expensive repair bills.

- More productivity. Don’t waste valuable production time waiting for your repair person to show up. When your staff is able to address smaller issues, you’re able to put your employees back to work more quickly.

- Prolong the life of your equipment. Motorized machinery is a big investment. Keep your equipment running longer with regular maintenance by your trained employee.

No matter what your business focuses on, you probably rely on electric motors for some part of it. The Electric Motors: Understanding and Troubleshooting course from NTT Training is a formal seminar that teaches your employees how to diagnose many electric motor issues. This 2-day class provides hands-on training for your maintenance, management, and engineering personnel. For added convenience, we bring the seminar right to your property. Contact our representatives to schedule your on-site seminar today.

For more information about National Technology Transfer or any of our programs click here: http://www.nttinc.com or http://www.nttinc.com/seminar-list-catalog/.

Recent Blog Posts

- Improve Plumbing Reliability and Compliance

- Optimize Steam System Performance with Regular Maintenance Audits

- Cost Effective Solutions for Meeting the NFPA Electrical Cycle of Safety

- Unlock the Efficiency of Boilers and Chillers with Proper Water Treatment

- Maximizing Boiler Efficiency: A Preventative Maintenance Tip for Your Team

- Categories

- Uncategorized (2)

- Electrical Training Programs (94)

- Code & Standards (29)

- Electrical Maintenance (18)

- Mechanical HVAC (8)

- Safety (39)

- Mechanical Training Programs (75)

- Code & Standards (10)

- Electrical Safety (8)

- HVAC (19)

- Maintenance (19)

- Fluid Power (19)

- News (13)

- Onsite Training (2)

- Contractor Management (1)

- National Electric Code (7)

- OSHA Rules and Requirements (19)

- General Safety Tips (4)

- Industrial Safety (4)

- Plumbing Standards (3)

- Electrical Blueprint Reading (6)

- Natural Gas Safety (3)

- Ultrasonic Testing (1)

- PLC (11)

- High Voltage (4)

- Oil Analysis (2)

- Centrifugal Pumps (4)

- Variable Frequency Drives (6)

- Welding Safety (7)

- Chillers (3)

- Hazardous Locations (5)

- Confined Spaces (6)

- Infrared Thermography (2)

- NFPA 72 (4)

- Process Control Loops (3)

- Backflow Prevention (1)

- Electrical Grounding (2)

- Industrial Circuits (2)

- Boilers (5)

- Shaft Alignment (3)

- Hoisting and Rigging (3)

- Fiber Optics (5)

- Refrigeration (1)

- Arc Flash (8)

- NFPA 110 (1)

- Conveyor Systems (1)

- NFPA 70E (2)

- Process Instruments (1)

- Vibration Analysis (1)

- Industrial Generators (2)

- Life Safety Code (4)

- Electrical Switchgear (1)

- NFPA 79 (2)

- Steam Distribution Systems (2)

- Preventative Maintenance (2)

- Electrical Codes & Standards (3)

- Mechanical Maintenance (5)

- Mechanical Fluid Power (1)

- Electrical Safety (2)

Filter Blogs

- July 2025 (1)

- June 2025 (1)

- April 2025 (2)

- March 2025 (1)

- February 2025 (1)

- January 2025 (1)

- December 2024 (1)

- November 2024 (1)

- October 2024 (1)

- September 2024 (1)

- August 2023 (1)

- July 2023 (1)

- June 2023 (1)

- April 2023 (1)

- March 2023 (1)

- February 2023 (1)

- December 2022 (1)

- October 2022 (1)

- August 2022 (1)

- July 2022 (1)

- October 2019 (9)

- September 2019 (8)

- August 2019 (9)

- July 2019 (8)

- June 2019 (8)

- May 2019 (9)

- April 2019 (9)

- March 2019 (7)

- February 2019 (4)

- January 2019 (9)

- December 2018 (7)

- November 2018 (7)

- October 2018 (9)

- September 2018 (6)

- August 2018 (7)

- July 2018 (9)

- June 2018 (8)

- May 2018 (9)

- April 2018 (9)

- March 2018 (8)

- February 2018 (8)

- January 2018 (9)

- December 2017 (9)

- November 2017 (8)

- October 2017 (9)

- September 2017 (8)

- August 2017 (7)

- July 2017 (5)

- June 2017 (7)

- May 2017 (8)

- April 2017 (3)

- March 2017 (7)

- February 2017 (3)

- January 2017 (4)

- December 2016 (7)

- November 2016 (4)

- October 2016 (7)

- September 2016 (5)

- August 2016 (6)

- June 2016 (1)

- May 2016 (2)

- April 2016 (2)

- March 2016 (1)

- January 2016 (2)

- October 2015 (1)

- August 2015 (1)

- July 2015 (3)

- May 2015 (1)

- January 2015 (3)

- April 2014 (4)

Our Mission:

Deliver solutions to our clients (and their global workforce) designed for safety, productivity and profitability.

Our Vision:

Empowering clients and their employees to be safe and skilled.

NTT Training Inc. has been accredited by the Accrediting Council for Continuing Education & Training (ACCET).

Better Business Bureau

Better Business Bureau

A Training Division of ECPI University