- Electrical Training

- Safety

- Electrical Compliance

- Electrical Automation

- Electrical Maintenance

- Mechanical Training

- HVAC

- Codes and Standards

- Fluid Power

- Maintenance

- View All Training Programs

-

View All Electrical Safety Training ProgramsTop Electrical Safety Training Programs

- Arc Flash Electrical Safety [Based on NFPA 70E®]

- Electrical Safety: NFPA 70E Refresher

- Electrical Safety Awareness

- Electrical Safety Practical Skills for Switchgear

- Electrical Safety: Power Generation, Transmission & Distribution [based on OSHA 1910.269]

- Seguridad Eléctrica en el centro de trabajo, [Basado en el manual NFPA 70E® 2021]

- Electrical Safety, Operation and Maintenance for Medium Voltage (MV) Distribution Systems and Equipment

- Train-The-Observer: Electrical Safety Field Observer Training

Upcoming Training Programs- 03/24 - 03/25 : Centennial , CO Electrical Safety, Operation and Maintenance for Medium Voltage (MV) Distribution Systems and Equipment

- 04/06 - 04/07 : Live Online Training , CO Arc Flash Electrical Safety [Based on NFPA 70E®]

- 04/30 - 04/30 : Centennial , CO Electrical Safety Practical Skills for Switchgear

- 05/04 - 05/05 : Live Online Training , CO Arc Flash Electrical Safety [Based on NFPA 70E®]

- 06/01 - 06/02 : Live Online Training , CO Arc Flash Electrical Safety [Based on NFPA 70E®]

-

View All Electrical Electrical Compliance Training ProgramsTop Electrical Electrical Compliance Training Programs

- 2026 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

- New Jersey 1 Hour Electrical Law (License Requirement)

- Electrical Systems: SOARES Grounding & Bonding

- Electrical Systems: Hazardous Locations

- NEC® – Analysis of Changes 2020 with Practical Exercises

- NFPA 110® – Emergency & Standby Power Systems

- NFPA 70B® Standard Overview

- NFPA 70B Standard for Electrical Equipment Maintenance (8-hr for Maintenance Technicians)

- NFPA 72: National Fire Alarm & Signaling Code®

- NFPA 79® – Electrical Standard For Industrial Machinery®

- NICET I & II

- National Electrical Safety Code® [NESC]

- NEC® – Analysis of Changes 2023

- Connecticut Four Hour 2025 Electricians Continuing Education Course

- 2023 National Electrical Code® With 2023 Washington State’s Electrical Code Amendments (based on Washington Administrative Code 296-46B)

Upcoming Training Programs- 04/08 - 04/10 : Centennial , CO 2026 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

- 04/08 - 04/10 : Live Online Training , CO 2026 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

- 04/29 - 04/30 : Live Online Training , CO Electrical Systems: Hazardous Locations

- 05/06 - 05/08 : Live Online Training , CO 2026 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

- 06/03 - 06/05 : Live Online Training , CO 2026 NFPA 70® – NATIONAL ELECTRICAL CODE® [NEC]

-

View All Electrical Electrical Automation Training ProgramsTop Electrical Electrical Automation Training Programs

- Instrumentation & Process Control

- PLCs [Programmable Logic Controllers]: Automation Systems

- PLCs [Programmable Logic Controllers]: ControlLogix & RSLogix 5000

- PLCs [Programmable Logic Controllers]: Fundamentals

- PLCs [Programmable Logic Controllers]: Siemens Simatic S7

- Tuning DDC/Process Control Loops

- Variable Frequency Drives [VFD]

Upcoming Training Programs -

View All Electrical Electrical Maintenance Training ProgramsUpcoming Training Programs

- 03/31 - 04/01 : Centennial , CO Basics of Industrial Electricity

- 04/02 - 04/03 : Centennial , CO Electrical Motor Control Circuits: Troubleshooting

- 04/07 - 04/09 : Centennial , CO Fiber Optics

- 05/12 - 05/13 : Centennial , CO Basics of Industrial Electricity

- 05/14 - 05/15 : Centennial , CO Electrical Motor Control Circuits: Troubleshooting

-

View All Mechanical HVAC Training ProgramsTop Mechanical HVAC Training Programs

- Balancing of Water and Air Systems

- Boilers: An Operational Workshop

- HVAC: Brazing [Advanced]

- Air Conditioning & Refrigeration: Advanced

- HVAC: Air Conditioning & Refrigeration

- HVAC: Principles of Heating & Ventilation

- Chillers: Operation & Maintenance of Chilled Water Systems

- Steam Distribution Systems

- Water Treatment for Boilers and Chilled Water Systems

- EPA 608 Certification Exam Preparation & Proctoring

Upcoming Training Programs- 03/24 - 03/26 : Centennial , CO Chillers: Operation & Maintenance of Chilled Water Systems

- 05/19 - 05/21 : Centennial , CO Boilers: An Operational Workshop

- 06/08 - 06/10 : Centennial , CO HVAC: Air Conditioning & Refrigeration

- 06/11 - 06/11 : Centennial , CO EPA 608 Certification Exam Preparation & Proctoring

- 06/12 - 06/12 : Live Online Training , CO EPA 608 Certification Exam Preparation & Proctoring

- View All Mechanical Codes and Standards Training Programs

- View All Mechanical Fluid Power Training Programs

-

View All Mechanical Maintenance Training ProgramsUpcoming Training Programs

- 05/05 - 05/06 : Centennial , CO Electric Motors: Understanding & Troubleshooting

- 05/07 - 05/08 : Centennial , CO Shaft Alignment with Laser Technology

- 07/28 - 07/29 : Centennial , CO Electric Motors: Understanding & Troubleshooting

- 08/06 - 08/07 : Centennial , CO Shaft Alignment with Laser Technology

- 11/03 - 11/04 : Centennial , CO Electric Motors: Understanding & Troubleshooting

Select the following link if you would like to recover a report that has been previously deleted.

NTT Blog

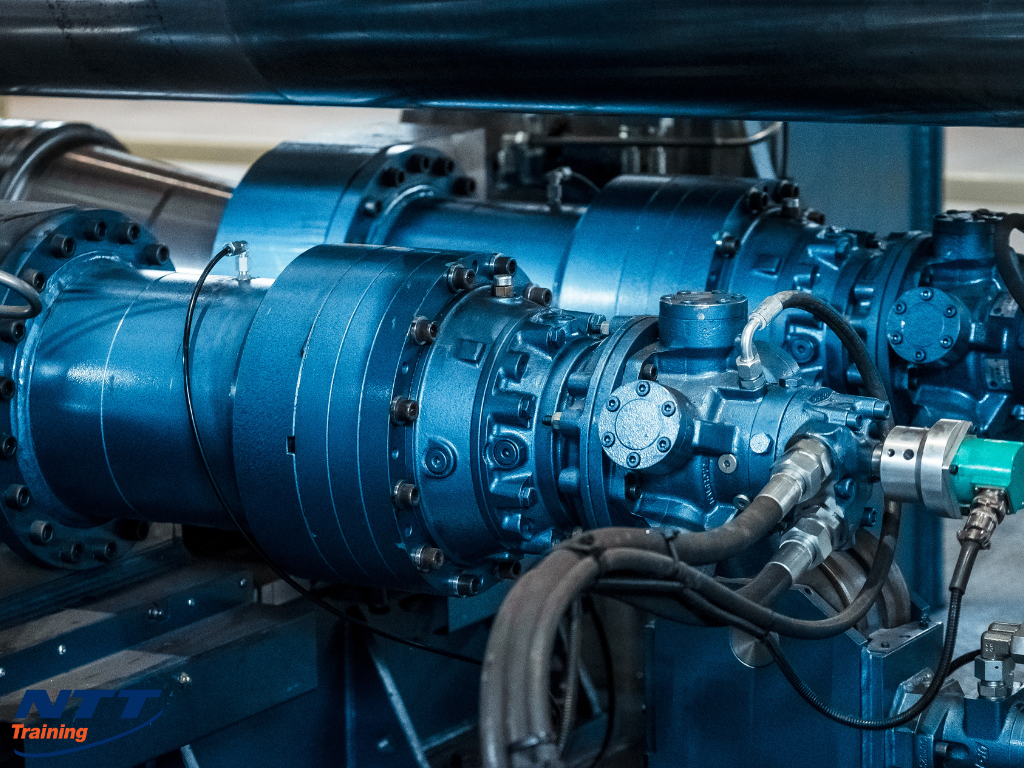

Industrial Hydraulics: Safety Training Every Facility Needs

Industrial hydraulics are mechanical machines that operate by employing force of liquid pressure. In industrial hydraulic-based machines, the mechanical displacement is produced by pumped, contained liquid, typically through piping that displace pistons.

Industrial hydraulics are component mechatronics, it combines electronics, mechanical and software engineering in the design and manufacturing of products. Industrial hydraulics leverage the power and intelligence developed via advanced hydraulics technology to break through limits and set new benchmarks for performance, life span and functionality.

Industrial hydraulics are designed with versatile and high performance monitoring and control components. These devices are tailor-made to meet different industrial applications. High systems performance and energy of the industrial hydraulics application are dependent on the power pack. Some of the systems have hydraulic servo pumps together with frequency converters and pressure sensors to enhance the performance levels and reduce energy consumption and the size of the hydraulic tank and the amount of piping installed.

Difference from Hydraulic Systems Utilized in Other Contexts

Industrial hydraulics are more or less the same us pneumatic systems in operation. Both the systems utilize fluids, but unlike pneumatics, industrial hydraulics utilize liquids rather than gasses. Industrial hydraulics are capable of intense pressure up to 10000 pounds per square inch (psi) unlike other pneumatic systems that can work at 100psi.

The high pressure exhibited by the industrial hydraulics is attributed to the incompressibility of fluid which allow them to achieve extreme power transfer with increased efficiency as energy is dissipated to compression, except in the case of pneumatic systems where air is utilized to fill the hydraulic lines. The fluid that are utilized in industrial hydraulic systems may cool, lubricate and transmit power simultaneously. Pneumatics are multifaceted in nature thus requiring lubrication and cooling.

Reasons Why Safety Training is Essential for all Your Workers

Numerous occupational standards and regulations explicitly requires you as the employer to train all your employee in all the health as safety aspects of their workplace. Occupational health and safety standards makes it your legal responsibility to limit certain tasks to competent, certified or qualified employees: meaning they have completed specialized training to perform specific duties and are aware of the health hazards. However, in any industrial set up it is essential to train all your employees to minimize risk or loss in case any hazard strikes.

Training help limit risks. You should incorporate hydraulic safety training into your company’s health and safety training process. Employee training needs should be based on their exposure to hydraulic systems. It enables them to identify the telltale signs of equipment that require maintenance thus saving time and money that would be incurred when conducting repairs.

Today, less than 1% of the industrial hydraulic systems comply with the OSHA’s Energy Control Procedure 1910.147 ©(4)(i). Training enables you to procedurally document, develop and utilize procedures to control potentially hazardous energy. It ensures that your employees are safe when engaging in their daily operations.

Benefits of Formal Training in Hydraulics

Formal training enables your employees to autonomously carry out daily checks (oil level, leaks, clogging filters) to avoid problems and actively schedule routine maintenance in a safe and efficient manner. It prevents loss of life and valuable equipment. Having certified professionals working for your company will thwart any non-compliance law suits in case of any hydraulic hazard.

It introduces proper safety measures that should be followed during maintenance. For instance, wearing personal protective equipment, refraining from solely relying on hydraulic lift when working on hydraulic components with the systems raised, unless bleeding the machine, it is not advisable to run the machine engine among other cautionary measures that will ensure safety of your workers and equipment.

Employees learn the proper procedures to employ when adjusting or removing any component. Releasing the hydraulic pressure is recommended before adjusting or removing any component. The hot fluid in the systems is normally under high pressure, a worker can sustain burns, cuts, bruises or fluid injection if not keen. Training workers enables them to refrain from mixing low and high pressure coupler components. Such mismatched components can lead to rapture in fitting of hose which can be fatal.

Training cautions your employees not to locate leaks in any hydraulic line using their hands, because, compressed fluid released through any leak can penetrate the skin or eyes, causing injection injuries. Instead, running a piece of paper, cardboard, wood or Plexiglas along the hydraulic line can help determine the location of the leak. Following proper procedures during such situations are properly covered through adequate training.

Does Your Facility Need Hydraulics Safety Training?

NTT Training is dedicated in providing appropriate training to help mitigate and reduce exposure to hydraulic hazards. You should consider enlisting your professionals to the Hydraulic and Systems Troubleshooting course to prepare them to properly thwart or mitigated any hydraulic hazards. Connect with us today for more information!

Recent Blog Posts

- Expert Guide to NEC Compliance in New Jersey

- Why Electrical Safety Observer Training Is the Missing Link in NFPA 70E Compliance

- NEC: National Electric Code (2026 edition)

- NFPA 79: Electrical Standard for Industrial Machinery (2024 Edition)

- EPA 608 Certification and Training

- Categories

- Uncategorized (6)

- Electrical Training Programs (96)

- Code & Standards (30)

- Electrical Maintenance (18)

- Mechanical HVAC (9)

- Safety (39)

- Mechanical Training Programs (75)

- Code & Standards (10)

- Electrical Safety (8)

- HVAC (19)

- Maintenance (19)

- Fluid Power (19)

- News (13)

- Onsite Training (2)

- Contractor Management (1)

- National Electric Code (9)

- OSHA Rules and Requirements (19)

- General Safety Tips (4)

- Industrial Safety (4)

- Plumbing Standards (3)

- Electrical Blueprint Reading (6)

- Natural Gas Safety (3)

- Ultrasonic Testing (1)

- PLC (11)

- High Voltage (4)

- Oil Analysis (2)

- Centrifugal Pumps (4)

- Variable Frequency Drives (6)

- Welding Safety (7)

- Chillers (3)

- Hazardous Locations (5)

- Confined Spaces (6)

- Infrared Thermography (2)

- NFPA 72 (4)

- Process Control Loops (3)

- Backflow Prevention (1)

- Electrical Grounding (2)

- Industrial Circuits (2)

- Boilers (5)

- Shaft Alignment (3)

- Hoisting and Rigging (3)

- Fiber Optics (5)

- Refrigeration (1)

- Arc Flash (8)

- NFPA 110 (1)

- Conveyor Systems (1)

- NFPA 70E (2)

- Process Instruments (1)

- Vibration Analysis (1)

- Industrial Generators (2)

- Life Safety Code (4)

- Electrical Switchgear (1)

- NFPA 79 (2)

- Steam Distribution Systems (2)

- Preventative Maintenance (2)

- Electrical Codes & Standards (5)

- Mechanical Maintenance (5)

- Mechanical Fluid Power (1)

- Electrical Safety (2)

Filter Blogs

- January 2026 (1)

- December 2025 (2)

- October 2025 (2)

- September 2025 (1)

- August 2025 (1)

- July 2025 (1)

- June 2025 (1)

- April 2025 (2)

- March 2025 (1)

- February 2025 (1)

- January 2025 (1)

- December 2024 (1)

- November 2024 (1)

- October 2024 (1)

- September 2024 (1)

- August 2023 (1)

- July 2023 (1)

- June 2023 (1)

- April 2023 (1)

- March 2023 (1)

- February 2023 (1)

- December 2022 (1)

- October 2022 (1)

- August 2022 (1)

- July 2022 (1)

- October 2019 (9)

- September 2019 (8)

- August 2019 (9)

- July 2019 (8)

- June 2019 (8)

- May 2019 (9)

- April 2019 (9)

- March 2019 (7)

- February 2019 (4)

- January 2019 (9)

- December 2018 (7)

- November 2018 (7)

- October 2018 (9)

- September 2018 (6)

- August 2018 (7)

- July 2018 (9)

- June 2018 (8)

- May 2018 (9)

- April 2018 (9)

- March 2018 (8)

- February 2018 (8)

- January 2018 (9)

- December 2017 (9)

- November 2017 (8)

- October 2017 (9)

- September 2017 (8)

- August 2017 (7)

- July 2017 (5)

- June 2017 (7)

- May 2017 (8)

- April 2017 (3)

- March 2017 (7)

- February 2017 (3)

- January 2017 (4)

- December 2016 (7)

- November 2016 (4)

- October 2016 (7)

- September 2016 (5)

- August 2016 (6)

- June 2016 (1)

- May 2016 (2)

- April 2016 (2)

- March 2016 (1)

- January 2016 (2)

- October 2015 (1)

- August 2015 (1)

- July 2015 (3)

- May 2015 (1)

- January 2015 (3)

- April 2014 (4)

Our Mission:

Deliver solutions to our clients (and their global workforce) designed for safety, productivity and profitability.

Our Vision:

Empowering clients and their employees to be safe and skilled.

NTT Training Inc. has been accredited by the Accrediting Council for Continuing Education & Training (ACCET).

Better Business Bureau

Better Business Bureau

A Training Division of ECPI University